At SAMEX, we manufacture cutting room equipment with a passion for perfecting what works well, and we continuously improve them based on feedback from our customers.

We have the largest stock of replacement parts for cutting machines in Poland and provide full, professional warranty service.

Have a look at our products categorised below.

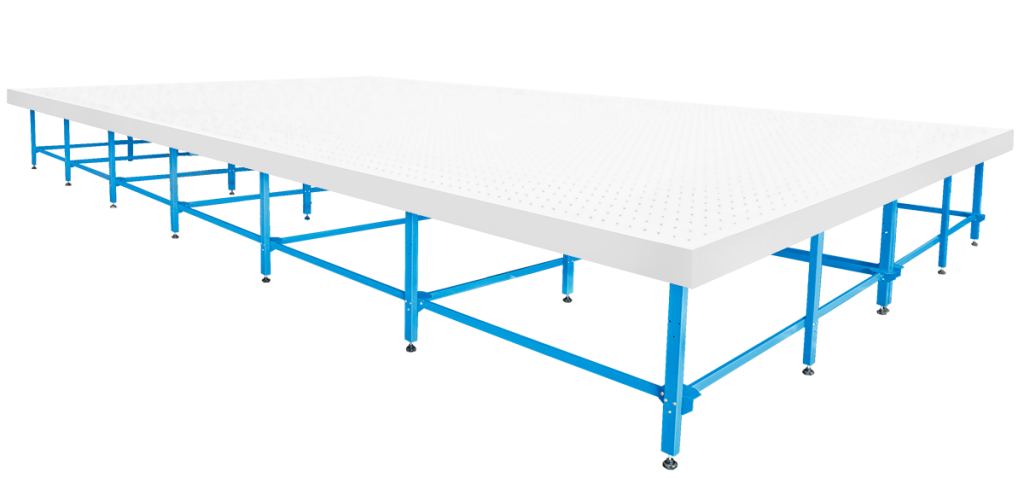

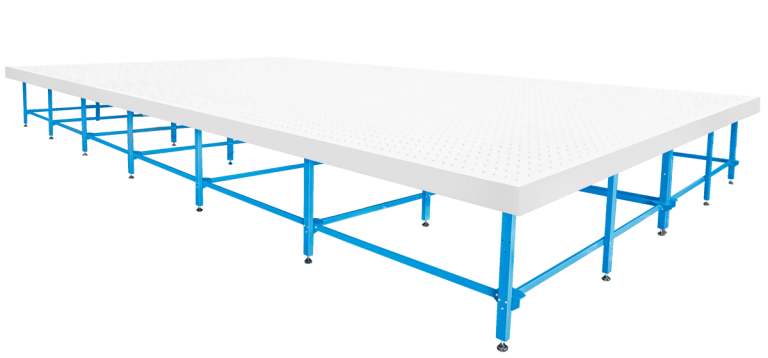

FlexiTable

fully customisable cutting table

The basic workplace in the cutting room, which can be equipped with an unwinder, end cutter, wheels and more. Its modular design makes it a good base for different applications.

Main applications

- apparel and garment, upholstery, home decor, automotive

- technical textiles, synthetics, industrial fabric production

When to choose it

- if you’re looking for a cost-effective solution

- if 5 mm cutting precision is enough for you

RollMaster

roller blinds cutting table

RollMaster is a multi-purpose cutting table for processing rolled materials into custom formats with 1 mm precision.

Main applications

- roller blinds, curtains, upholstery, bedding, leather

- industrial filters, banners, canvas, tarpaulins, technical fabrics

When to choose it

- if you cut rectangles with an accuracy of 1 mm

- if you need a sealed edge with an ultrasonic cutter

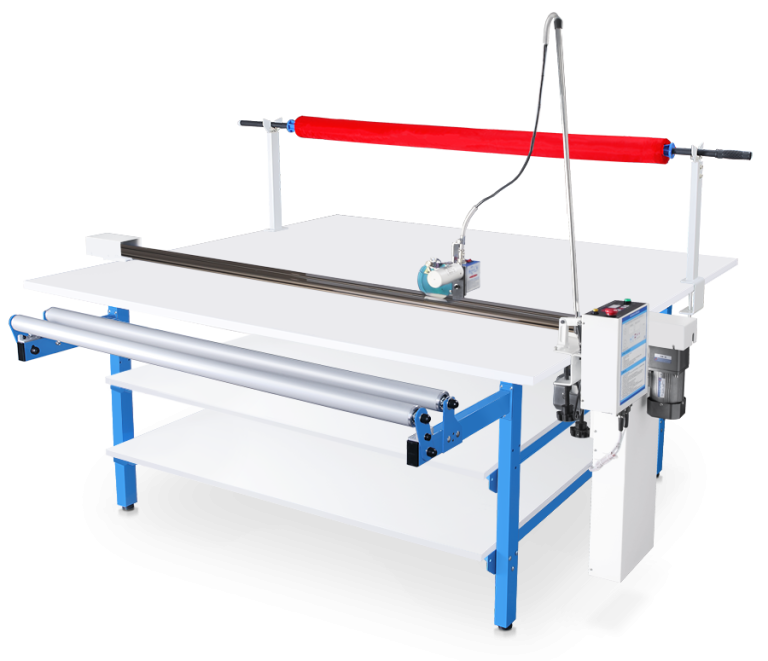

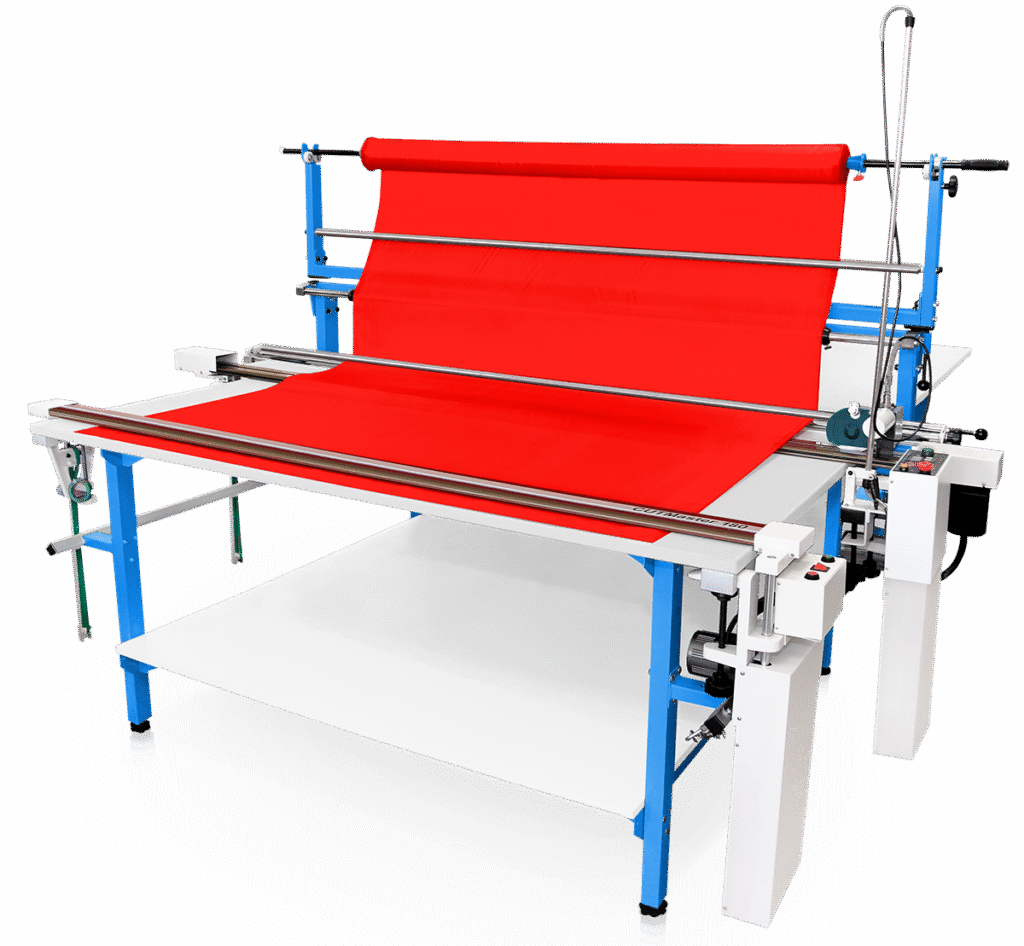

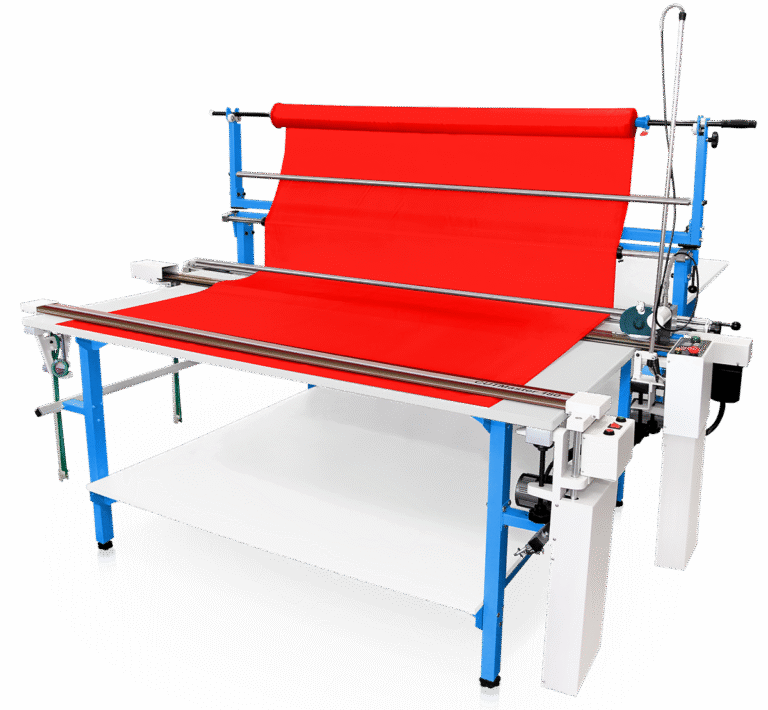

CUTMaster

spreading cutting table

CUTMaster is a series of cutting tables designed for manual material spreading. It speeds up the cutting process by up to 100% compared to traditional unwinding methods.

Main applications

- clothes, uniforms, lingerie, underwear

- bedding, curtains, upholstery, automotive

When to choose it

- if you want to spread and cut multiple layers of material

- if 5 mm cutting precision is enough for you

WindMaster

rewinding machine

Rewinding cutting tables help to transfer fabric from one roll to another to measure and cut specific lengths accurately.

Main applications

- curtains, quality control and fabric inspection

- for fabric warehouses

When to choose it

- if you measure and cut rolled materials into shorter lengths

- when you need to cut pieces longer than the table

EasyRoll

fabric unwinders

Essential accessories for the end cutter, providing a controlled feed of material to be cut. EasyRoll unwinders include table-top models, frame-mounted units, and both stationary and mobile versions.

Main applications

- unrolling materials from the rolls for further processing

When to choose it

- if you need to cut materials from the rolls

AIRMaster

air blowing table

AIRMaster tables function as conveyor tables, hemming stations for carpets or rugs, and for various types of materials that require processing with frequent movement.

Main applications

- carpets hemming

- facilitating heavy object transportation

When to choose

- if you need to hem carpets with ease

- if you need to move heavy items effortlessly

VACMaster

vacuum table

This cutting table uses a vacuum suction system to hold materials in place during the cutting process.

Main applications

- for plotters and cutters

- sails cutting

When to choose it

- if the material needs to be held in place while cutting

- if you need to compress thick materials before cutting

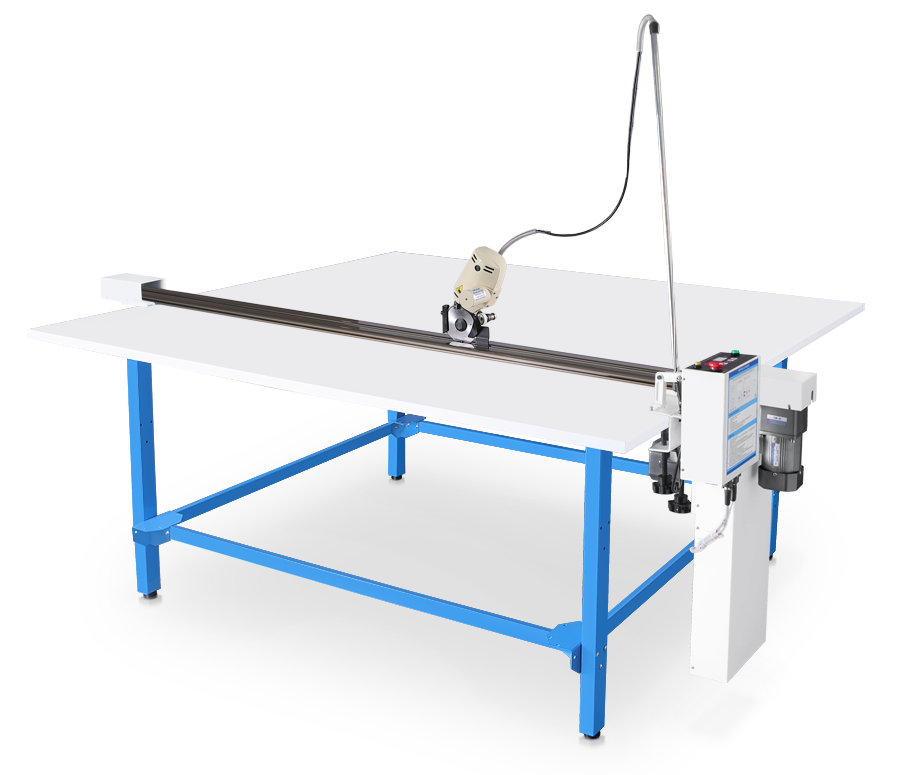

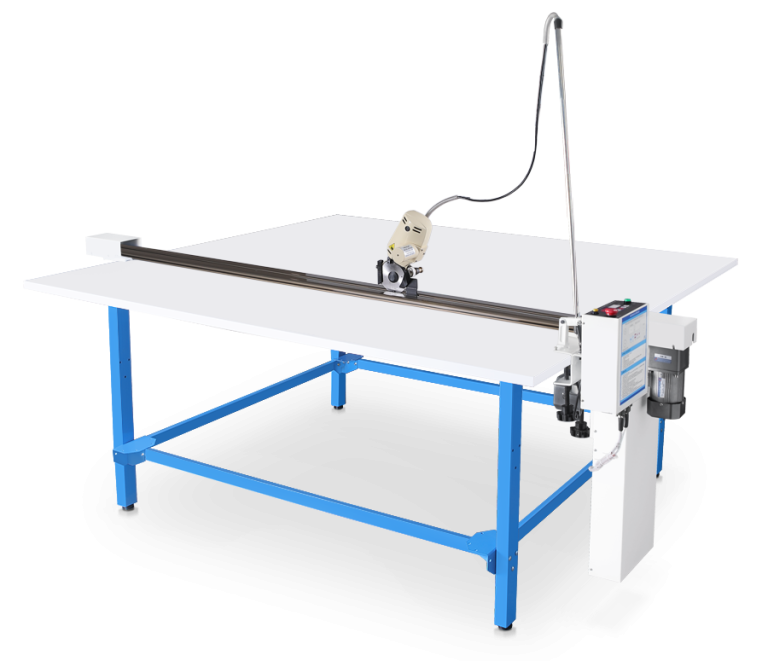

End Cutters

fabric cutting machines

End cutters enable quick cutting of successive fabric layers.

Available in manual and automatic versions, they can be equipped with optional pressure bar to secure material during cutting.

Main applications

- cotton, linen, denim, jersey, silk, woven fabric, leather, polyester

- vinyl, films, technical textiles, synthetic fibres, filter materials

When to choose it

- if you already own a cutting table

Cutting Machines

manual cutting machines

Cutting machines are essential equipment in any cutting room. Our range includes vertical, circular, and band knife machines available in various cutting height, motor power, and cordless options tailored to specific tasks.

Main applications

- clothes, uniforms, lingerie, undearwear

- bedding, curtains, upholstery, cleaning cloth

Main applications

- clothes, uniforms, lingerie, undearwear

- bedding, curtains, upholstery, cleaning cloth

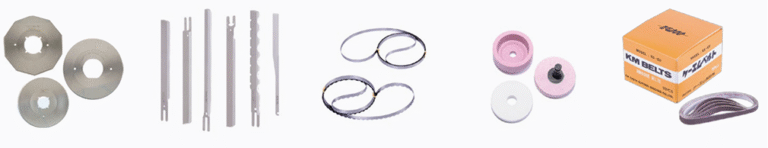

Wearables and Spare Parts

everything needed for maintenance

In daily cutting room work, it is essential to avoid downtime caused by worn maintenance parts. We keep a large supply of blades and grinding stones in stock, as well as spare parts for repairing the machines.