AIRMaster

Stop pulling, start sliding.

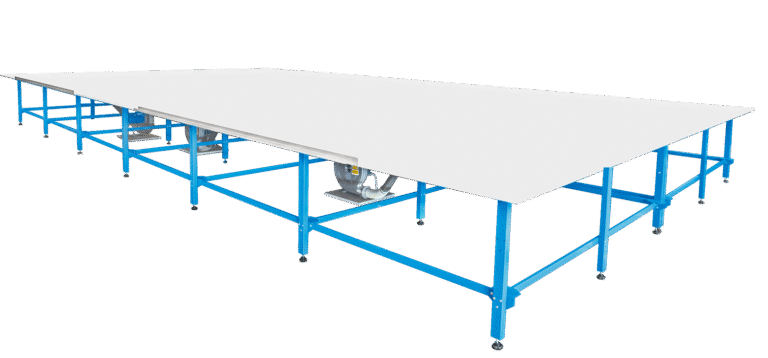

AIRMaster air blowing tables use powerful fans to create an air cushion, eliminating friction and allowing effortless movement of heavy materials and objects.

Effortless Material Handling for Heavy Carpets and Industrial Production

Moving heavy carpets and rugs across a work surface typically requires multiple workers and causes serious physical strain. AIRMaster solves this problem — one person can effortlessly move even the heaviest carpets in any direction.

This air blowing technology transforms carpet hemming and rug production operations. Instead of pushing and pulling materials, workers simply guide them across the frictionless surface. The result is faster production, reduced worker fatigue, and better quality since materials aren’t dragged or damaged.

Two Models for Different Needs

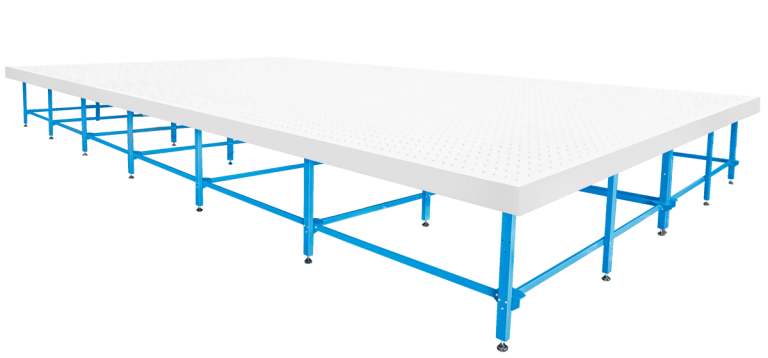

AIRMaster offers an air blowing system for general fabric handling and binding small carpets. It features modular design, segmented blower control for energy efficiency, and customisable sizing.

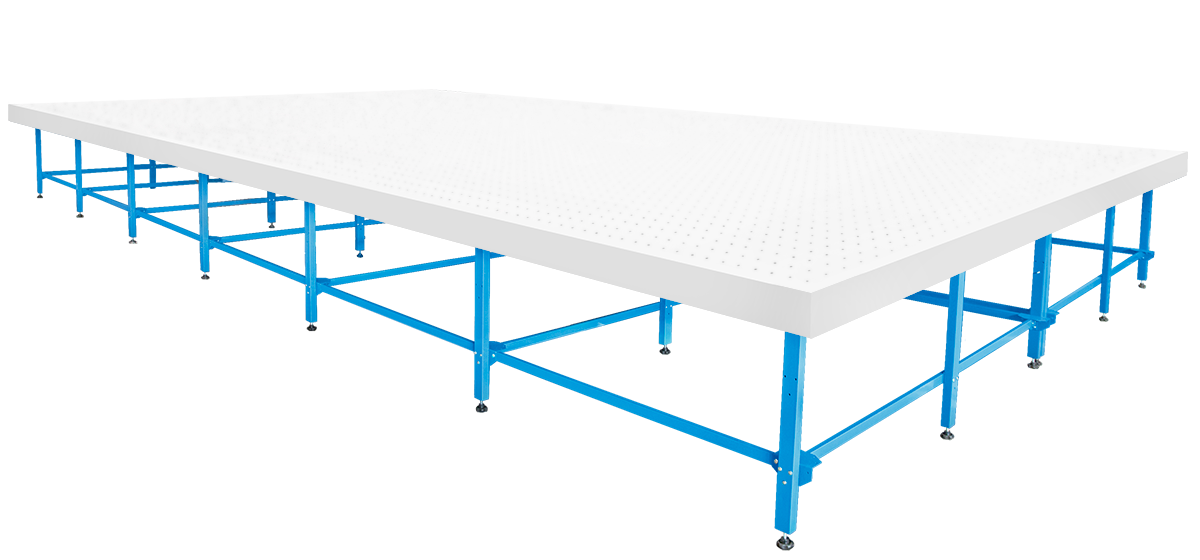

AIRMaster PRO is recommended for heavy carpets. It includes 14 cm thick air chambers (significantly thicker than standard model), direct fan connection with no external piping, much larger air flow capacity and adjustable blowing force. These enhancements handle the heaviest carpets while providing precise movement control.

Heavy Objects Transportation

AIRMaster can also work as a conveyor table for heavy objects — not only flexible materials. The table can be equipped with ball transfer units that create smooth rolling points across the surface. Heavy items like doors, panels or glass sheets glide easily, allowing one person to move objects that would normally require lifting equipment or multiple workers. This makes material flow faster and safer in furniture manufacturing, door production and similar industries.

Strong and Expandable

The robust steel construction handles heavy industrial loads while remaining surprisingly easy to install. The modular design means you can start with a basic size and expand later — there’s no upper limit to table dimensions. Custom configurations suit any production space, from compact workshops to large facilities.

Real Benefits for Production

For carpet hemming operations, productivity gains are substantial. Materials flow smoothly along hem machines instead of requiring constant physical effort. The AIRMaster system also works for technical textiles, multiple fabric layers during cutting operations, and any heavy object needing frequent repositioning.

Whether you’re running a custom rug shop or a large factory, air blowing tables reduce labour costs, prevent workplace injuries, and convert multi-person material handling into simple operations for one person.

AIRMaster can be any size

Choose dimensions and options that match your requirements.

AIRMaster

Stop pulling, start sliding.

AIRMaster air blowing tables use powerful fans to create an air cushion, eliminating friction and allowing effortless movement of heavy materials and objects.

Effortless Material Handling for Heavy Carpets and Industrial Production

Moving heavy carpets and rugs across a work surface typically requires multiple workers and causes serious physical strain. AIRMaster solves this problem — one person can effortlessly move even the heaviest carpets in any direction.

This air blowing technology transforms carpet hemming and rug production operations. Instead of pushing and pulling materials, workers simply guide them across the frictionless surface. The result is faster production, reduced worker fatigue, and better quality since materials aren’t dragged or damaged.

Two Models for Different Needs

AIRMaster offers an air blowing system for general fabric handling and binding small carpets. It features modular design, segmented blower control for energy efficiency, and customisable sizing.

AIRMaster PRO is recommended for heavy carpets. It includes 14 cm thick air chambers (significantly thicker than standard model), direct fan connection with no external piping, much larger air flow capacity and adjustable blowing force. These enhancements handle the heaviest carpets while providing precise movement control.

Heavy Objects Transportation

AIRMaster can also work as a conveyor table for heavy objects — not only flexible materials. The table can be equipped with ball transfer units that create smooth rolling points across the surface. Heavy items like doors, panels or glass sheets glide easily, allowing one person to move objects that would normally require lifting equipment or multiple workers. This makes material flow faster and safer in furniture manufacturing, door production and similar industries.

Strong and Expandable

The robust steel construction handles heavy industrial loads while remaining surprisingly easy to install. The modular design means you can start with a basic size and expand later — there’s no upper limit to table dimensions. Custom configurations suit any production space, from compact workshops to large facilities.

Real Benefits for Production

For carpet hemming operations, productivity gains are substantial. Materials flow smoothly along hem machines instead of requiring constant physical effort. The AIRMaster system also works for technical textiles, multiple fabric layers during cutting operations, and any heavy object needing frequent repositioning.

Whether you’re running a custom rug shop or a large factory, air blowing tables reduce labour costs, prevent workplace injuries, and convert multi-person material handling into simple operations for one person.

AIRMaster can be any size

Choose dimensions and options that match your requirements.