Faster spreading, lower costs.

Built to boost your productivity

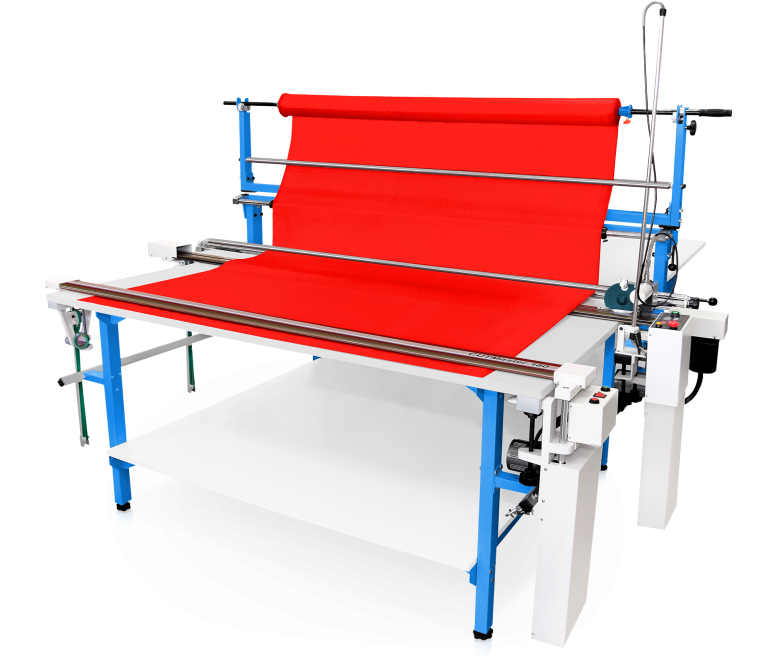

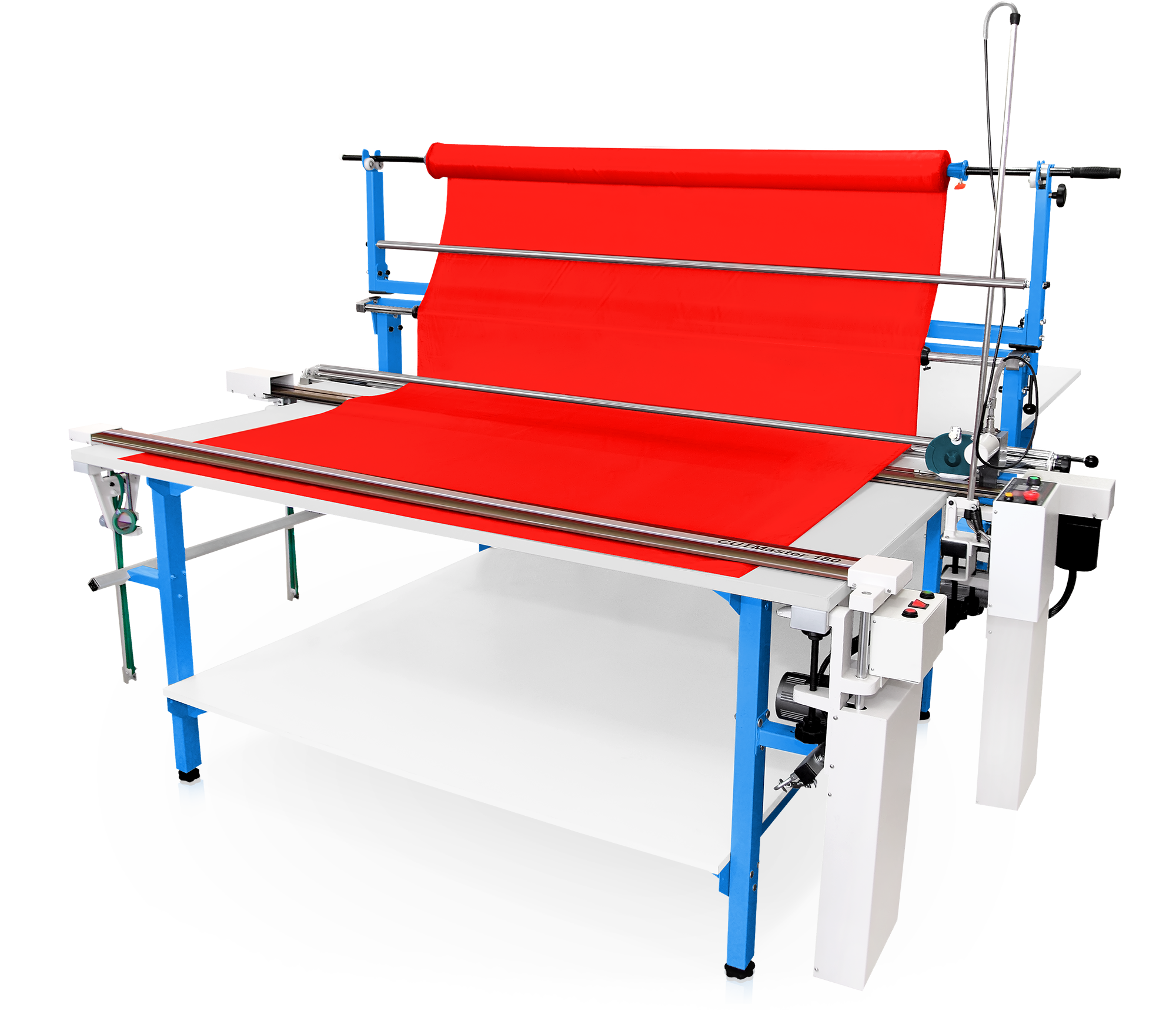

CUTMaster fabric spreading machine speeds up unwinding and cutting consecutive layers of material. It combines manual spreading control with automatic cutting speed.

Let us introduce a professional CUTMaster cutting tables series dedicated to spreading and cutting all kinds of fabrics.

Faster Spreading with Lower Costs

Traditional unwinding is slow and tiring, often requiring two people for larger materials. Fully automatic spreading machines accelerate work significantly, but their cost is not economically justified for many companies.

CUTMaster speeds up spreading typically by 50% to over 100% compared to manual methods, and with most materials it can be performed by one person. An average roll is spread across the table within 15 minutes, not an hour.

The automatic cutting head enables cutting with an accuracy of 5 mm and a speed of 1 m/s. The table handles materials up to 320 cm wide with spreading height of 20 cm for multi-layer cutting.

Work is Easier with Smart Technology

The manually operated spreading process gives operators complete control over fabric tension and alignment — very important for elastic materials like jersey, lycra, or sportswear.

The CUTMaster AIR model features the air blowing function which solves a real problem: moving a large stack of heavy denim or upholstery fabric. The air cushion system allows one operator to easily position materials that would normally require two people. You can activate air blowing for selected table sections only, combining standard and air-assisted areas based on your working method.

For heavy industrial materials, the reinforced spreading carriage handles fabric rolls up to 150 kg. Even with that weight, the trolley moves smoothly thanks to precise tracks and high-quality bearing rolls.

Customisable Configurations for Every Production Need

From fashion to industrial applications, CUTMaster spreading tables fit perfectly. Whether you’re producing clothing, bedding, automotive upholstery or industrial insulation, it will help you deliver quality products with lower costs.

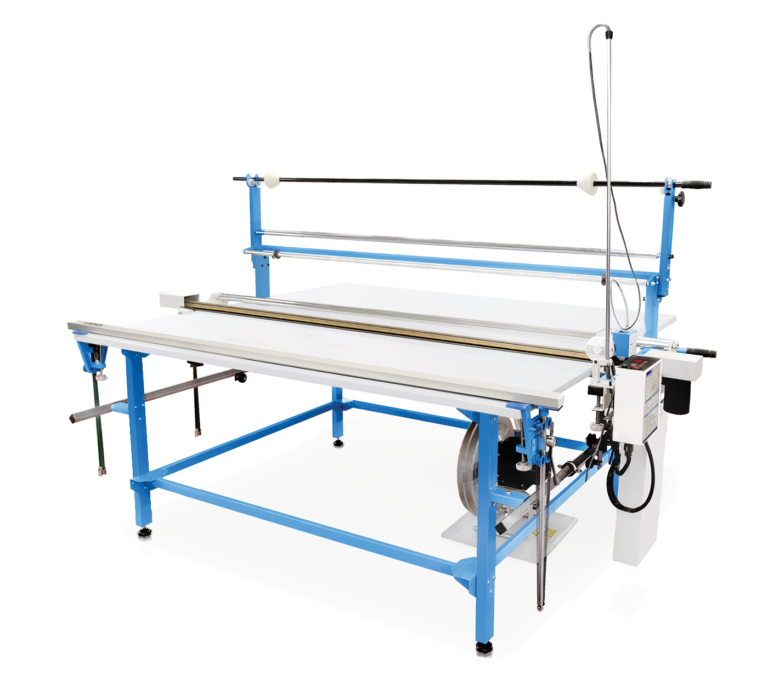

CUTMaster features extensive customisation: from pneumatic holding bar, rotating carriage and paper dispenser to basket unwinders, blade speed adjustment and lower shelves.

Two types of cutting heads are available — up to 5 mm for thin materials (Standard and Super models), up to 25 mm for thick ones in Super Plus.

Fast to Pay Off

CUTMaster is designed for long-term use with minimal maintenance costs — just blade and sharpener replacement. The investment typically pays for itself within months thanks to one-person operation.

We use two types of cutters, which we recommend depending on the material type. When in doubt, we test samples and select the appropriate device.

Intuitive, fast and convenient operation was the major priority when designing the CUTMaster series. All repetitive tasks have been simplified to a minimum to save time.

Every CUTMaster can be

configured to your needs

Choose dimensions and options that match your requirements.

Faster spreading, lower costs.

Built to boost your productivity

CUTMaster fabric spreading machine speeds up unwinding and cutting consecutive layers of material. It combines manual spreading control with automatic cutting speed.

Let us introduce a professional CUTMaster cutting tables series dedicated to spreading and cutting all kinds of fabrics.

Faster Spreading with Lower Costs

Traditional unwinding is slow and tiring, often requiring two people for larger materials. Fully automatic spreading machines accelerate work significantly, but their cost is not economically justified for many companies.

CUTMaster speeds up spreading typically by 50% to over 100% compared to manual methods, and with most materials it can be performed by one person. An average roll is spread across the table within 15 minutes, not an hour.

The automatic cutting head enables cutting with an accuracy of 5 mm and a speed of 1 m/s. The table handles materials up to 320 cm wide with spreading height of 20 cm for multi-layer cutting.

Work is Easier with Smart Technology

The manually operated spreading process gives operators complete control over fabric tension and alignment — very important for elastic materials like jersey, lycra, or sportswear.

The CUTMaster AIR model features the air blowing function which solves a real problem: moving a large stack of heavy denim or upholstery fabric. The air cushion system allows one operator to easily position materials that would normally require two people. You can activate air blowing for selected table sections only, combining standard and air-assisted areas based on your working method.

For heavy industrial materials, the reinforced spreading carriage handles fabric rolls up to 150 kg. Even with that weight, the trolley moves smoothly thanks to precise tracks and high-quality bearing rolls.

Customisable Configurations for Every Production Need

From fashion to industrial applications, CUTMaster spreading tables fit perfectly. Whether you’re producing clothing, bedding, automotive upholstery or industrial insulation, it will help you deliver quality products with lower costs.

CUTMaster features extensive customisation: from pneumatic holding bar, rotating carriage and paper dispenser to basket unwinders, blade speed adjustment and lower shelves.

Two types of cutting heads are available — up to 5 mm for thin materials (Standard and Super models), up to 25 mm for thick ones in Super Plus.

Fast to Pay Off

CUTMaster is designed for long-term use with minimal maintenance costs — just blade and sharpener replacement. The investment typically pays for itself within months thanks to one-person operation.

We use two types of cutters, which we recommend depending on the material type. When in doubt, we test samples and select the appropriate device.

Intuitive, fast and convenient operation was the major priority when designing the CUTMaster series. All repetitive tasks have been simplified to a minimum to save time.

Every CUTMaster can be

configured to your needs

Choose dimensions and options that match your requirements.