Manual cutting machines are the basic appliances in the cutting room.

From simple patterns to complex shapes, from silk to fiberglass, from a few layers to the high volume – for each of these applications you will find a suitable cutting device.

You can choose among very different groups of machines: vertical, circular, band knives or ultrasonic, with different cutting height and different power motors, intended for specific tasks. We invite you to have a look at our offer.

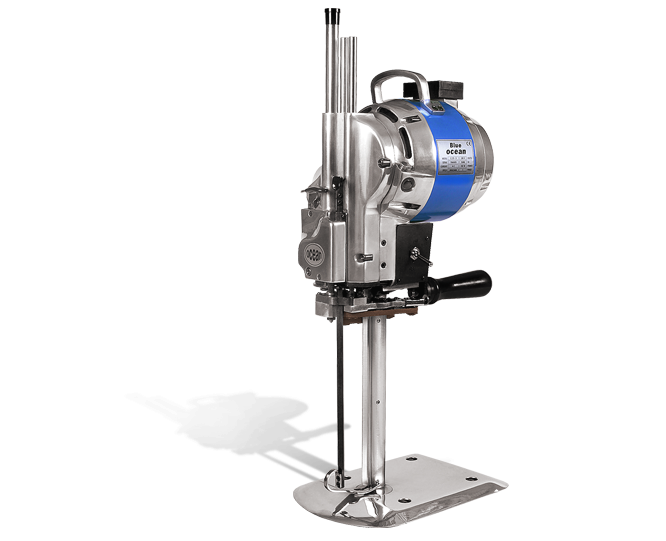

Straight Knife Machines

Straight knife cutting machines are the most versatile option for cutting rooms. They handle simple straight cuts and complex curved patterns with ease. These machines are ideal for cutting multiple fabric layers stacked on the cutting table. Available in various cutting heights and motor powers, vertical knife cutting machines suit everything from lightweight apparel fabrics to thick upholstery materials.

Round Knife Machines

Round knife cutting machines are commonly used to cut straight lines or large curves. The rotating circular blade delivers faster cutting speeds than straight knives for linear cuts. Cordless battery-powered versions offer mobility around the cutting room. Whilst round knife machines aren’t suited for tight curves or complex shapes, they’re unmatched for quickly cutting straight edges and trimming materials.

Band Knife Machines

Band knife cutting machines combine the pattern-cutting versatility of straight knives with significantly improved speed and precision. The continuous loop blade cuts through high material stacks more efficiently than handheld cutters. Band knives are particularly effective for cutting thick material layers where precision matters – such as clothing patterns, furniture upholstery and automotive interiors.

Ultrasonic Cutters

Ultrasonic knives operate at high-frequency resonance, making them ideal for synthetic, non-woven and thermoplastic materials. The ultrasonic vibrations simultaneously cut and weld synthetic fabric edges, eliminating fraying and the need for seams or stitches. This technology is environmentally friendly – producing no waste, noise, odours, or toxic fumes during operation.

Compliance and Support

All machines meet EU safety standards, including protection against accidental blade activation after power failures. We stock spare parts and provide service support for brands including Eastman, KM, Maimin, Wolf, Kuris, Ocean, Hoffman, Vibromat, Rexel, Dayang and others.

Manual cutting machines are the basic appliances in the cutting room.

From simple patterns to complex shapes, from silk to fiberglass, from a few layers to the high volume – for each of these applications you will find a suitable cutting device.

You can choose among very different groups of machines: vertical, circular, band knives or ultrasonic, with different cutting height and different power motors, intended for specific tasks. We invite you to have a look at our offer.

Straight Knife Machines

Straight knife cutting machines are the most versatile option for cutting rooms. They handle simple straight cuts and complex curved patterns with ease. These machines are ideal for cutting multiple fabric layers stacked on the cutting table. Available in various cutting heights and motor powers, vertical knife cutting machines suit everything from lightweight apparel fabrics to thick upholstery materials.

Round Knife Machines

Round knife cutting machines are commonly used to cut straight lines or large curves. The rotating circular blade delivers faster cutting speeds than straight knives for linear cuts. Cordless battery-powered versions offer mobility around the cutting room. Whilst round knife machines aren’t suited for tight curves or complex shapes, they’re unmatched for quickly cutting straight edges and trimming materials.

Band Knife Machines

Band knife cutting machines combine the pattern-cutting versatility of straight knives with significantly improved speed and precision. The continuous loop blade cuts through high material stacks more efficiently than handheld cutters. Band knives are particularly effective for cutting thick material layers where precision matters – such as clothing patterns, furniture upholstery and automotive interiors.

Ultrasonic Cutters

Ultrasonic knives operate at high-frequency resonance, making them ideal for synthetic, non-woven and thermoplastic materials. The ultrasonic vibrations simultaneously cut and weld synthetic fabric edges, eliminating fraying and the need for seams or stitches. This technology is environmentally friendly – producing no waste, noise, odours, or toxic fumes during operation.

Compliance and Support

All machines meet EU safety standards, including protection against accidental blade activation after power failures. We stock spare parts and provide service support for brands including Eastman, KM, Maimin, Wolf, Kuris, Ocean, Hoffman, Vibromat, Rexel, Dayang and others.