Strong, simple, ready to use.

Unwinders that ensure smooth material flow

A fabric unwinder is essential textile equipment for controlled material feeding to cutting machines. We offer a comprehensive range of manual unwinders, including table top models, frame-mounted units, and both stationary and mobile versions.

Six Types for Various Needs

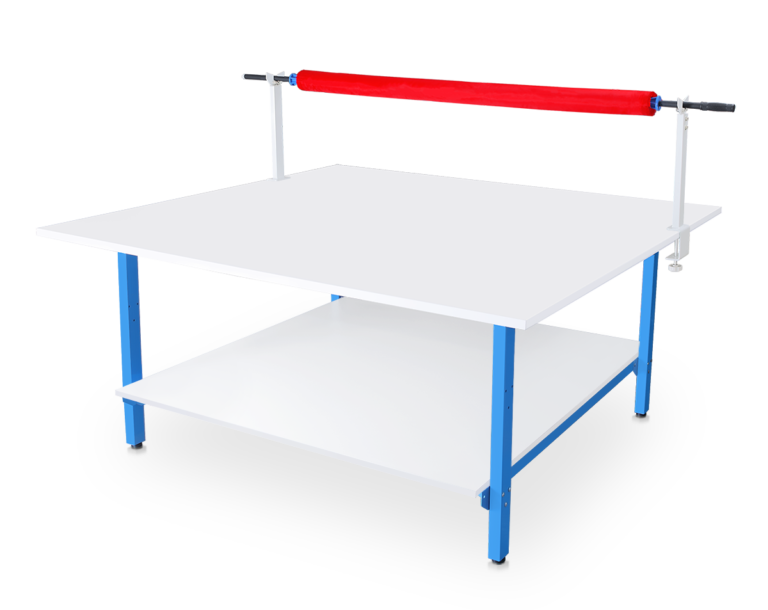

Table top unwinders are mounted to the edge of the cutting table. The material unwinds smoothly as it is pulled across the table to the cutter. The simplest version has a single tube, but we recommend a version with an additional tube which guides the material parallel to the table without causing skewed unwinding.

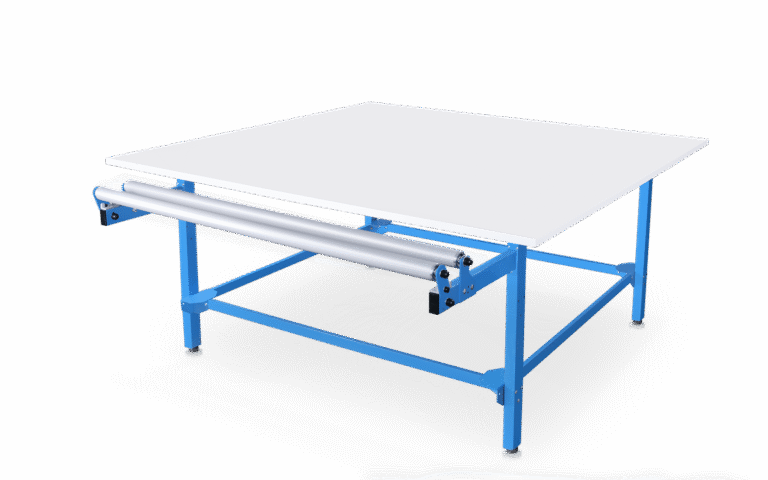

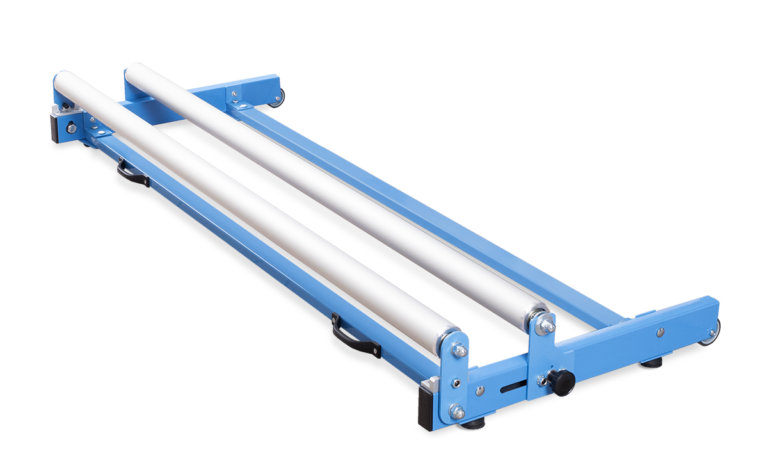

Roller unwinders are mounted to the cutting table frame. It is available as an option for the FlexiTable, but we can adapt it to any table frame if you provide us with its dimensions. The unwinder has two tubes, on which a roll rests on the table top level, and the material is unrolled directly onto the table to the cutter.

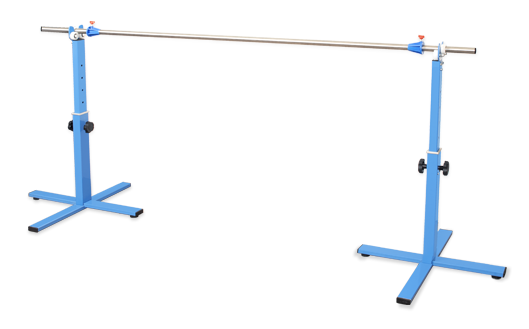

Stationary unwinders are available in two configurations. The single-tube version is our most popular model. The double-tube version allows you to work with two different materials or have a spare roll ready for a quick change.

Floor unwinders are freestanding or movable. Different types accommodate rolls up to 120 cm of diameter.

Mobile basket unwinder is a cradle mounted on the frame with wheels. You can move it anywhere, lock the wheels, and create a stable feed station. It handles rolls weighing up to 80 kg and is especially effective for materials without cores or with damaged edges that don’t fit on the tube.

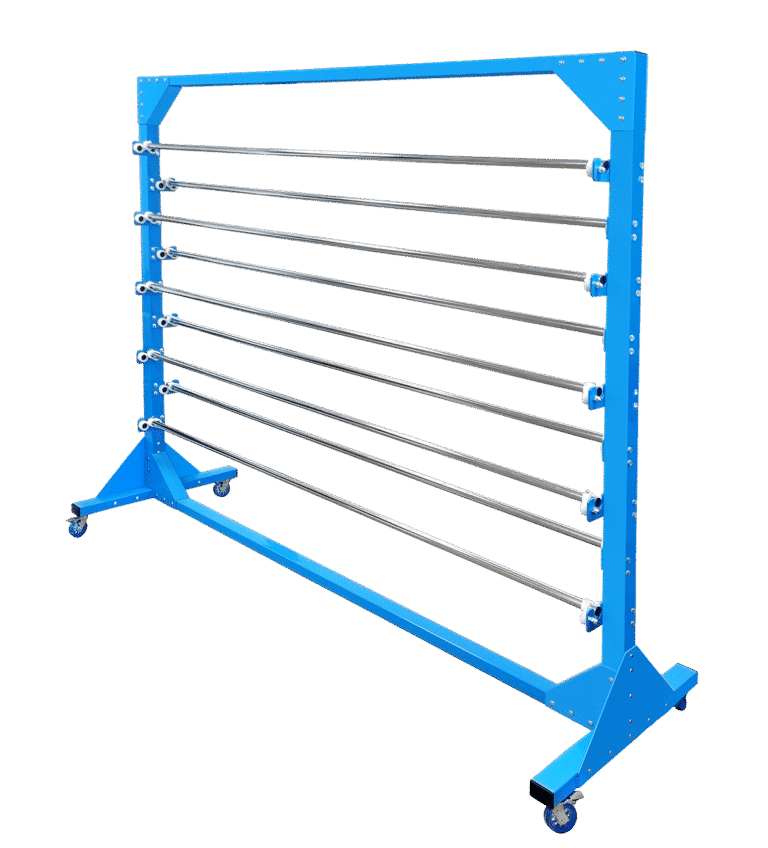

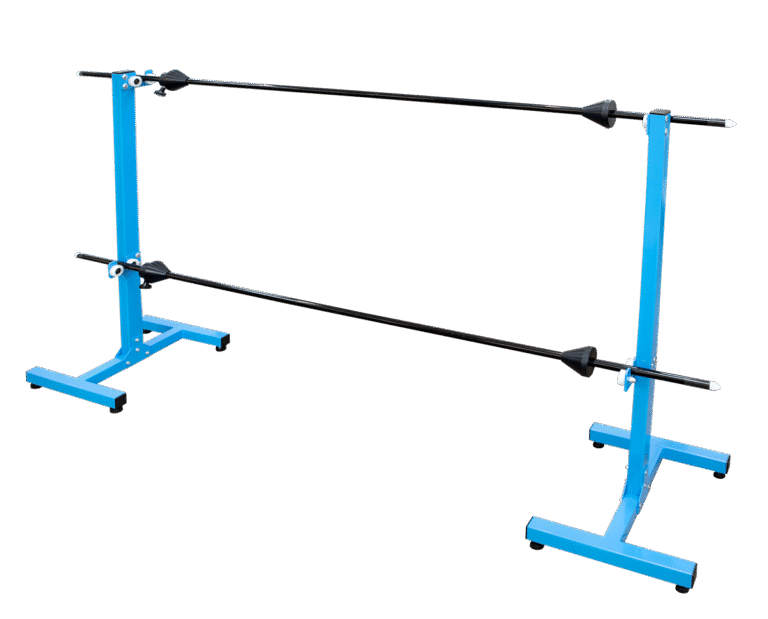

Multi-roll unwinders are large, movable racks with space for up to 9 rolls stacked vertically. Each roll rests on its own tube support, allowing you to pre-load multiple materials. You can switch between materials without removing the rolls — simply pull the one you need. Perfect for cutting different materials throughout the day.

Why Simple Solutions Work Best

For many cutting operations, manual fabric unwinders’ simplicity is exactly what’s needed. No motor or electronics maintenance required. No training required for tension control systems. No breakdowns that halt production. Simply reliable material support that increases cutting efficiency.

Choose the type of unwinder that suits your typical roll weight and workspace layout — it’s a small investment that makes every cutting job easier.

Stable fabric feeding reduces waste and improves cutting precision

Multiple configurations to match your workspace and material requirements

Strong, simple, ready to use.

Unwinders that ensure smooth material flow

A fabric unwinder is essential textile equipment for controlled material feeding to cutting machines. We offer a comprehensive range of manual unwinders, including table top models, frame-mounted units, and both stationary and mobile versions.

Six Types for Various Needs

Table top unwinders are mounted to the edge of the cutting table. The material unwinds smoothly as it is pulled across the table to the cutter. The simplest version has a single tube, but we recommend a version with an additional tube which guides the material parallel to the table without causing skewed unwinding.

Roller unwinders are mounted to the cutting table frame. It is available as an option for the FlexiTable, but we can adapt it to any table frame if you provide us with its dimensions. The unwinder has two tubes, on which a roll rests on the table top level, and the material is unrolled directly onto the table to the cutter.

Stationary unwinders are available in two configurations. The single-tube version is our most popular model. The double-tube version allows you to work with two different materials or have a spare roll ready for a quick change.

Floor unwinders are freestanding or movable. Different types accommodate rolls up to 120 cm of diameter.

Mobile basket unwinder is a cradle mounted on the frame with wheels. You can move it anywhere, lock the wheels, and create a stable feed station. It handles rolls weighing up to 80 kg and is especially effective for materials without cores or with damaged edges that don’t fit on the tube.

Multi-roll unwinders are large, movable racks with space for up to 9 rolls stacked vertically. Each roll rests on its own tube support, allowing you to pre-load multiple materials. You can switch between materials without removing the rolls — simply pull the one you need. Perfect for cutting different materials throughout the day.

Why Simple Solutions Work Best

For many cutting operations, manual fabric unwinders’ simplicity is exactly what’s needed. No motor or electronics maintenance required. No training required for tension control systems. No breakdowns that halt production. Simply reliable material support that increases cutting efficiency.

Choose the type of unwinder that suits your typical roll weight and workspace layout — it’s a small investment that makes every cutting job easier.

Stable fabric feeding reduces waste and improves cutting precision

Multiple configurations to match your workspace and material requirements