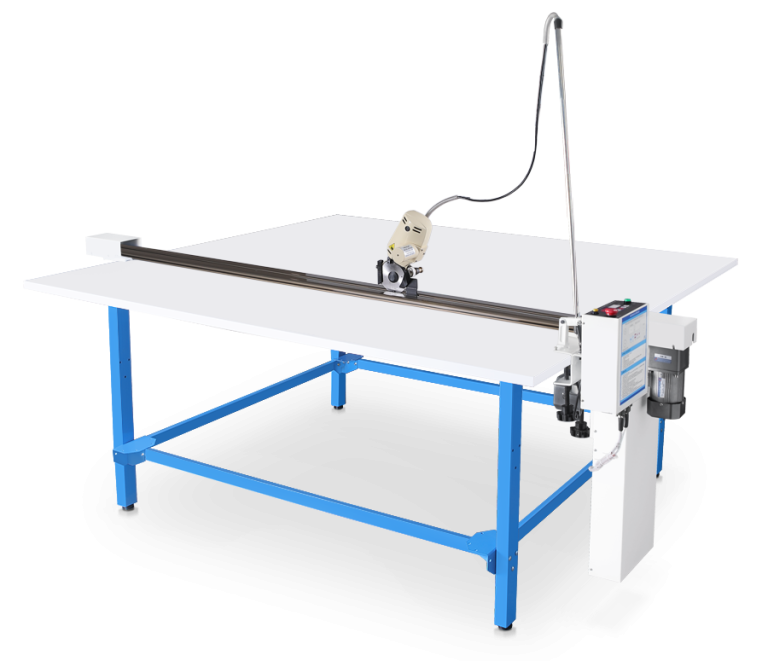

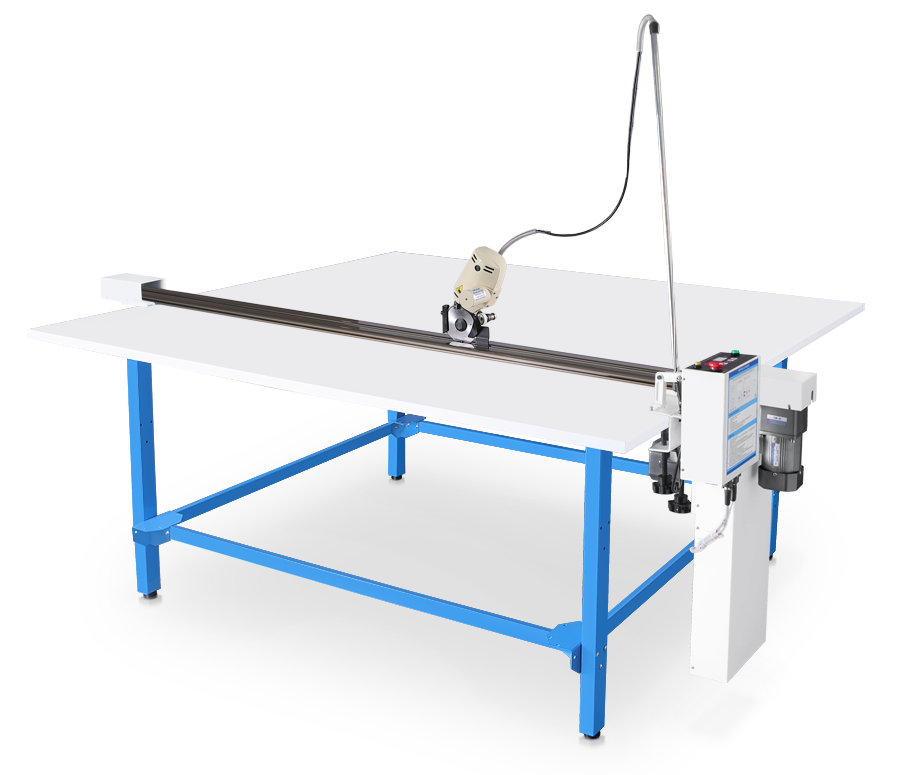

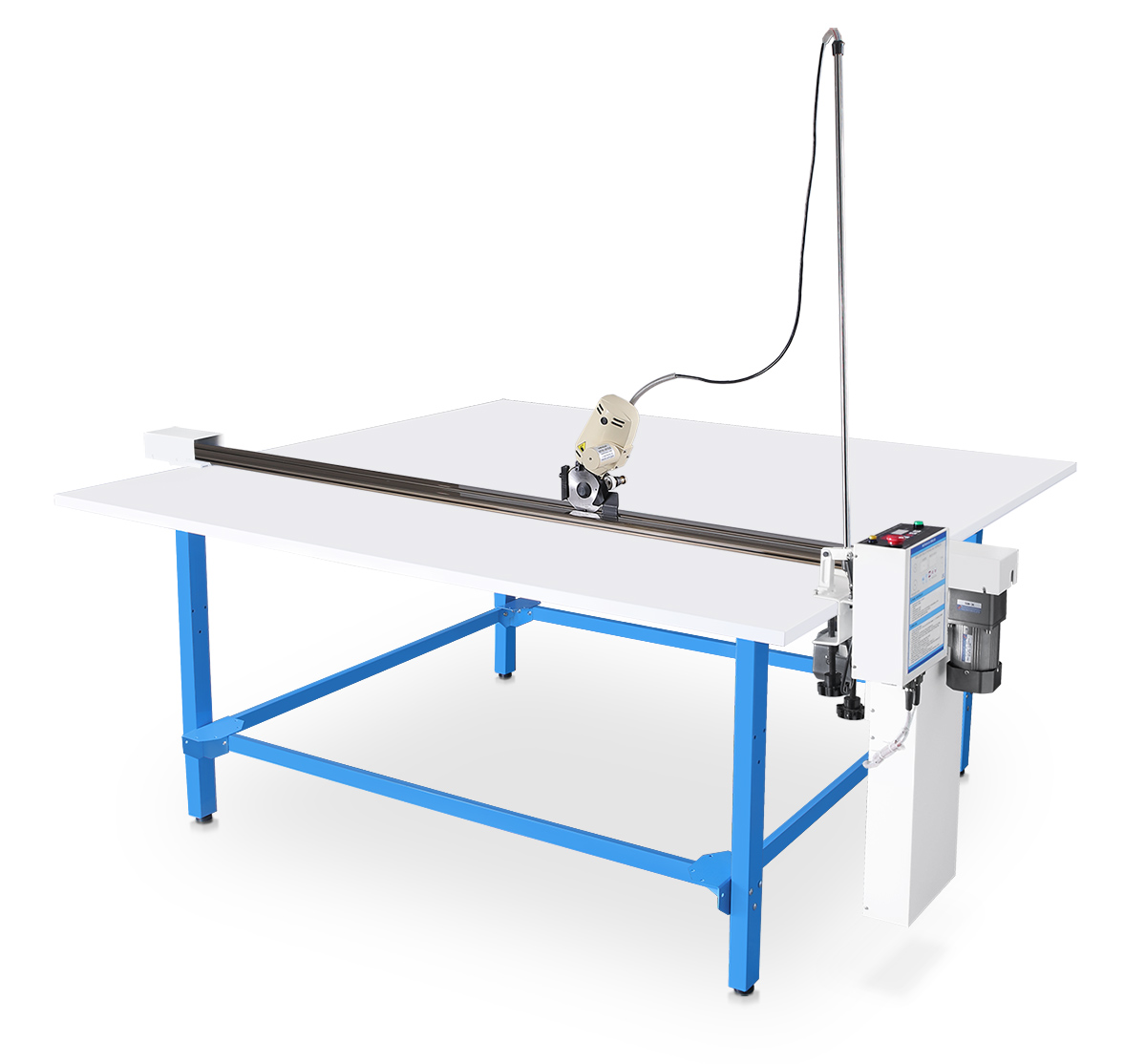

End cutters are fabric cutting machines designed for quick, accurate cutting of single or multiple layers from the roll. The cutting head moves along a rail, which length is adjusted to match your cutting table width.

Manual or Automatic Operation

Manual end cutters offer simple, cost-effective cutting for medium-volume production. The operator moves the cutting head along the track rail while the high-speed motor (12,000 rpm) cuts through materials up to 5 mm thick. The built-in counter shows number of cut layers, which can be edited. The parking brake holds the track rail in the upper position over the material (this feature is added by us). Manual versions include a fabric rewinder that mounts directly to the table.

Automatic end cutters increase productivity through motorised movement along the track rail. The cutting head automatically travels at 1 m/s cutting speed. After the cutting process is done, the track rail raises automatically allowing the cut fabric to fall onto previously cut layers. Standard DYDB-2 version handles materials up to 5 mm thick, while the high-capacity DYDB-2B version cuts materials up to 25 mm thick using an octagonal blade at 800 rpm.

Track rail lengths differ — manual model features cutting width up to 260 cm, while automatic versions allow for 330 cm.

Fabric Pressure Bars for Better Results

We highly recommend adding a pressure bar to secure material during cutting. Two versions are available:

The manual pressure bar provides reliable material hold-down for standard fabrics. It uses the gravitational force to keep fabrics in place during the cutting process.

The pneumatic pressure bar delivers significantly stronger clamping force – essential when cutting thin materials or slippery fabrics that shift during cutting. Pneumatic version ensures strong pressure across the entire cutting width.

Complete Cutting Solutions

End cutters work seamlessly with fabric unwinders to create efficient cutting stations. They handle diverse materials from delicate silks to heavy industrial fabrics. Choose manual operation for lower investment or automatic versions for high-volume production.

All models are compatible with any cutting table. Use them with your current table or or consider our FlexiTable for an integrated solution.

End cutters are fabric cutting machines designed for quick, accurate cutting of single or multiple layers from the roll. The cutting head moves along a rail, which length is adjusted to match your cutting table width.

Manual or Automatic Operation

Manual end cutters offer simple, cost-effective cutting for medium-volume production. The operator moves the cutting head along the track rail while the high-speed motor (12,000 rpm) cuts through materials up to 5 mm thick. The built-in counter shows number of cut layers, which can be edited. The parking brake holds the track rail in the upper position over the material (this feature is added by us). Manual versions include a fabric rewinder that mounts directly to the table.

Automatic end cutters increase productivity through motorised movement along the track rail. The cutting head automatically travels at 1 m/s cutting speed. After the cutting process is done, the track rail raises automatically allowing the cut fabric to fall onto previously cut layers. Standard DYDB-2 version handles materials up to 5 mm thick, while the high-capacity DYDB-2B version cuts materials up to 25 mm thick using an octagonal blade at 800 rpm.

Track rail lengths differ — manual model features cutting width up to 260 cm, while automatic versions allow for 330 cm.

Fabric Pressure Bars for Better Results

We highly recommend adding a pressure bar to secure material during cutting. Two versions are available:

The manual pressure bar provides reliable material hold-down for standard fabrics. It uses the gravitational force to keep fabrics in place during the cutting process.

The pneumatic pressure bar delivers significantly stronger clamping force – essential when cutting thin materials or slippery fabrics that shift during cutting. Pneumatic version ensures strong pressure across the entire cutting width.

Complete Cutting Solutions

End cutters work seamlessly with fabric unwinders to create efficient cutting stations. They handle diverse materials from delicate silks to heavy industrial fabrics. Choose manual operation for lower investment or automatic versions for high-volume production.

All models are compatible with any cutting table. Use them with your current table or or consider our FlexiTable for an integrated solution.