Any size, any need, one solution.

Built to fit any cutting room

The cutting table is the primary place of work in the cutting room, so when planning this investment, it’s worth choosing quality workmanship and reliability that ensures safe operation for years.

While designing FlexiTable we have put a lot of effort to make the construction light, yet exceptionally stable and durable.

Like all SAMEX products, FlexiTable combines functionality with high aesthetics.

Modular System for Easy Expansion

FlexiTable allows any length in 1.40 m segments. We offer standard widths from 1.82 m to 3.20 m and custom sizes available on request. Height adjustment in the range of 86–90 cm allows for adjustment to various preferences and levelling. Tables arrive pre-assembled for quick installation in your cutting room.

The construction features special girder nodes that combine lightweight with high stiffness. The 25 mm thick table top has a solid surface with strong PVC edging that protects the table edges. The powder-coated steel frame meet demands of daily industrial use while remaining easy to install.

Choose Your Configuration

Choose from pre-defined models or build your own configuration. Each table can be equipped with variety of accessories, such as an unwinder, cutter, wheels, bottom shelves and more.

Flexi Start

Basic cutting table expandable with optional equipment when needed.

Choose it when starting your business, for simple cutting operations, or as a base for custom configuration with your own equipment.

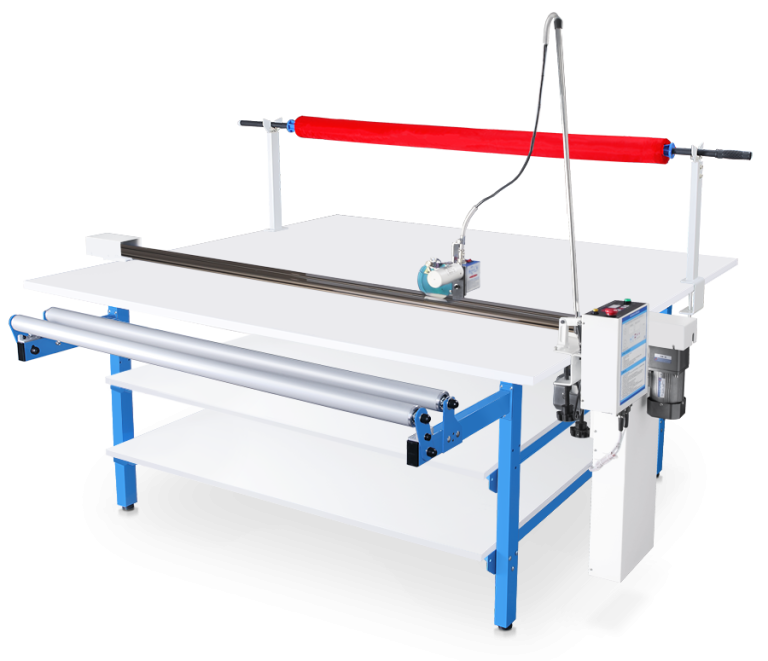

Flexi Standard

This model is equipped with the Long Ocean DYDB-1 manual cutter and a simple unwinder. Even for low-scale production, this is a breakthrough compared to cutting layers with scissors. The operator moves the cutting head along the track rail while the high-speed motor cuts materials up to 5 mm thick.

Flexi Standard can be modified to your needs — choose table size, upgrade the unwinder, or add a holding bar. It’s simple with our configuration tool.

Flexi Super

Faster and more efficient than manual version, Long Ocean DYDB-2 automatic end cutter is the core of the Flexi Super cutting table. It features a cutting speed of 1 m/s, automatic rail lifting after each cut and adjustable travel distance. No more pushing and pulling the cutting head — just press a button.

Like other models, Flexi Super can also be re-configured in a way you want.

Flexi Super Plus

Super Plus version is equipped with the high-capacity Long Ocean DYDB-2B end cutter, which handles materials up to 25 mm thick using an octagonal blade at 800 rpm (compared to 5 mm and 12,000 rpm on the Flexi Super model).

Choose it for thick, harder materials which require slower blade movement.

Modular design allows any size of the table and the possibility to easily expand when needed

FlexiTable is delivered pre-assembled, making the installation quick and easy

Each FlexiTable model can be

customised to your needs

Choose dimensions and equipment that fit your production type.

Create your own setup with easy-to-use online tool.

Any size, any need, one solution.

Built to fit any cutting room

The cutting table is the primary place of work in the cutting room, so when planning this investment, it’s worth choosing quality workmanship and reliability that ensures safe operation for years.

While designing FlexiTable we have put a lot of effort to make the construction light, yet exceptionally stable and durable.

Like all SAMEX products, FlexiTable combines functionality with high aesthetics.

Modular System for Easy Expansion

FlexiTable allows any length in 1.40 m segments. We offer standard widths from 1.82 m to 3.20 m and custom sizes available on request. Height adjustment in the range of 86–90 cm allows for adjustment to various preferences and levelling. Tables arrive pre-assembled for quick installation in your cutting room.

The construction features special girder nodes that combine lightweight with high stiffness. The 25 mm thick table top has a solid surface with strong PVC edging that protects the table edges. The powder-coated steel frame meet demands of daily industrial use while remaining easy to install.

Choose Your Configuration

Choose from pre-defined models or build your own configuration. Each table can be equipped with variety of accessories, such as an unwinder, cutter, wheels, bottom shelves and more.

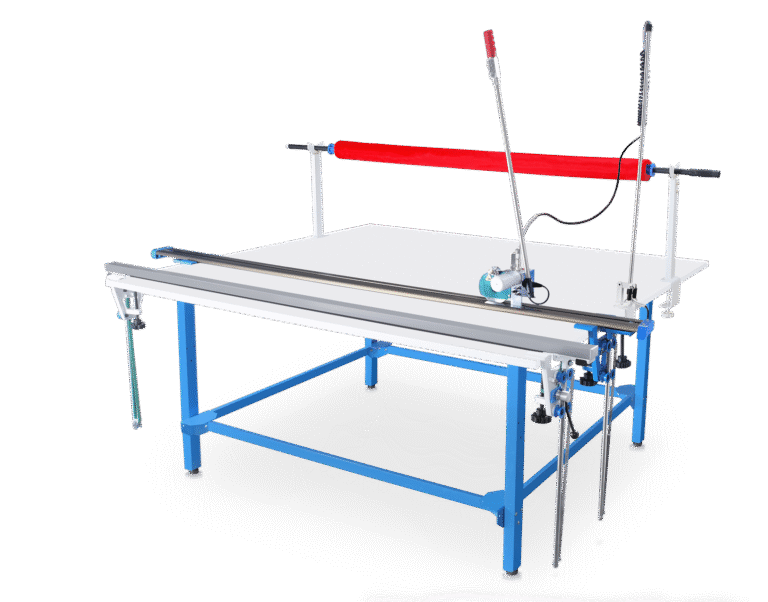

Flexi Start

Basic cutting table expandable with optional equipment when needed.

Choose it when starting your business, for simple cutting operations, or as a base for custom configuration with your own equipment.

Flexi Standard

This model is equipped with the Long Ocean DYDB-1 manual cutter and a simple unwinder. Even for low-scale production, this is a breakthrough compared to cutting layers with scissors. The operator moves the cutting head along the track rail while the high-speed motor cuts materials up to 5 mm thick.

Flexi Standard can be modified to your needs — choose table size, upgrade the unwinder, or add a holding bar. It’s simple with our configuration tool.

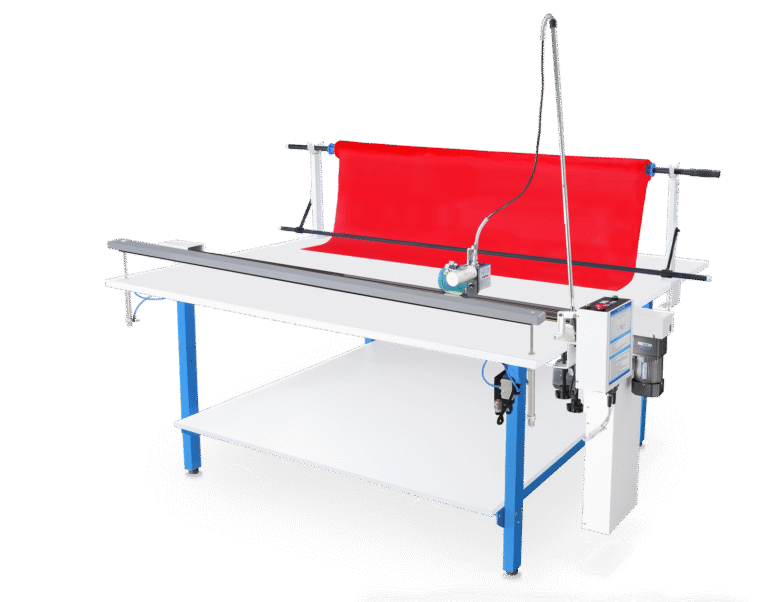

Flexi Super

Faster and more efficient than manual version, Long Ocean DYDB-2 automatic end cutter is the core of the Flexi Super cutting table. It features a cutting speed of 1 m/s, automatic rail lifting after each cut and adjustable travel distance. No more pushing and pulling the cutting head — just press a button.

Like other models, Flexi Super can also be re-configured in a way you want.

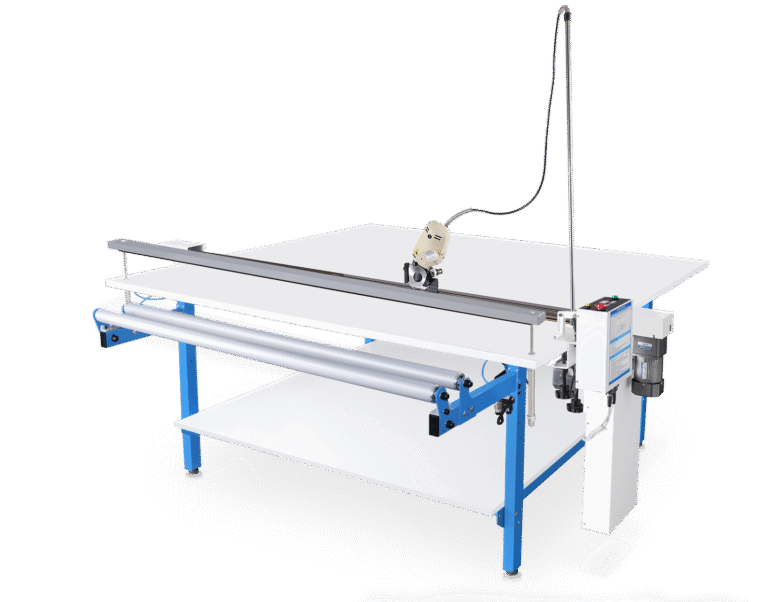

Flexi Super Plus

Super Plus version is equipped with the high-capacity Long Ocean DYDB-2B end cutter, which handles materials up to 25 mm thick using an octagonal blade at 800 rpm (compared to 5 mm and 12,000 rpm on the Flexi Super model).

Choose it for thick, harder materials which require slower blade movement.

Modular design allows any size of the table and the possibility to expand limitlessly.

Each FlexiTable model can be

customised to your needs

Choose dimensions and equipment that fit your production type.

Create your own setup with easy-to-use online tool.