RollMaster. One series, multiple solutions.

Designed for diverse production types

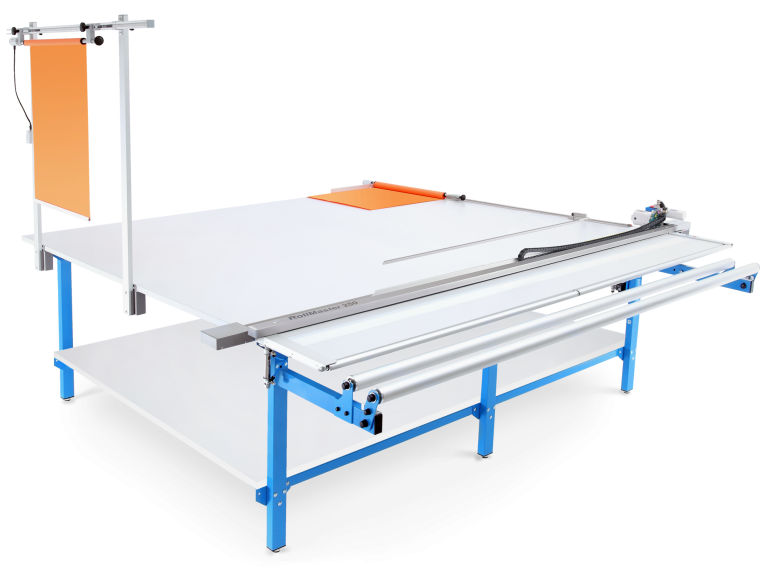

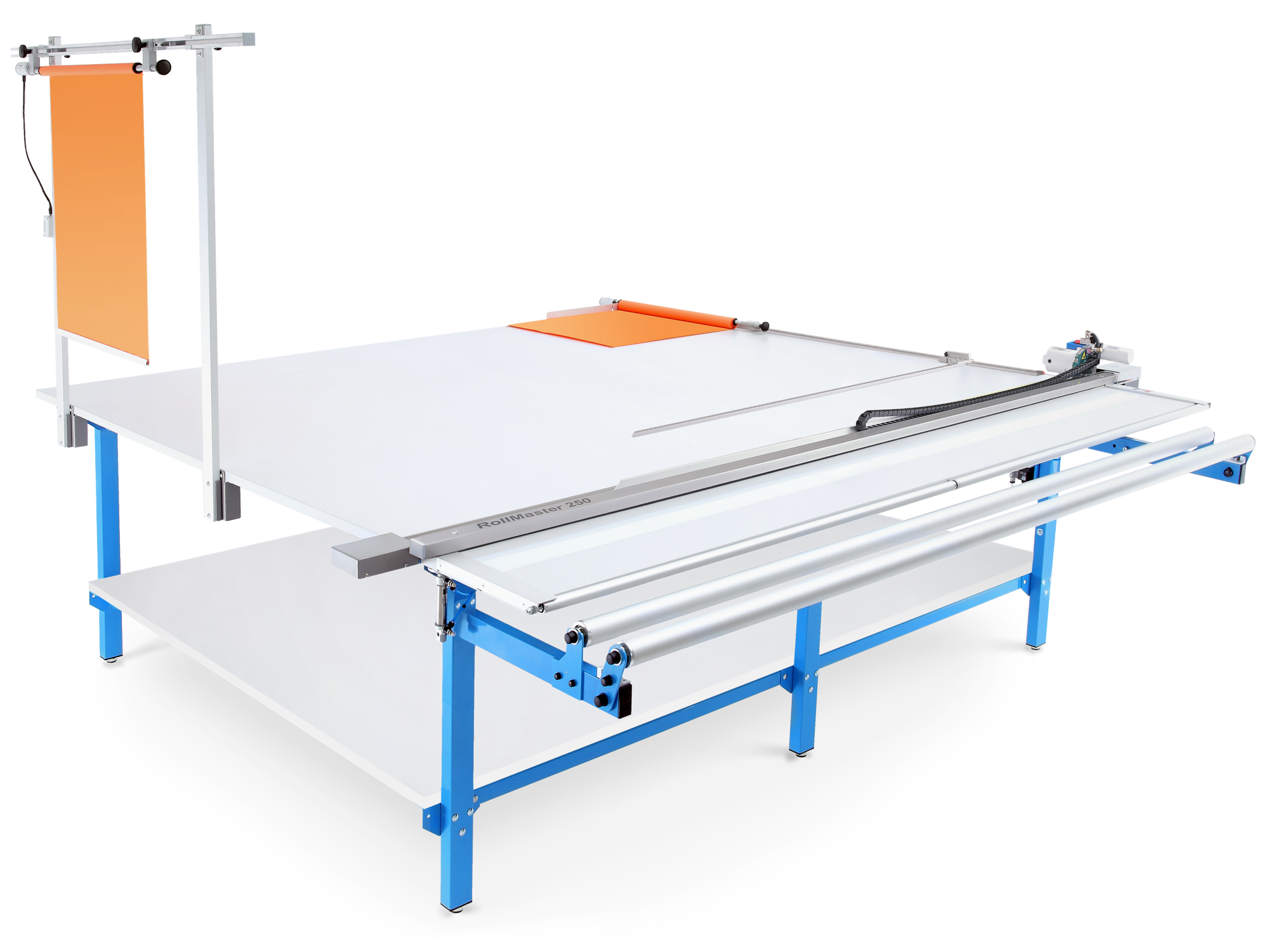

RollMaster is a multi-purpose cutting table for precise cutting of materials into custom formats.

We designed the RollMaster series to fill a real gap we saw in the industrial cutting table market — something between basic manual cutting and expensive automated solutions that many companies can’t afford or don’t need.

While Industry 4.0 solutions demand huge infrastructure investments, RollMaster gives you precision cutting for a fraction of the price. We call it smart simplicity because it delivers real results and is affordable for companies of each size.

Precise Cutting For Multiple Industries

RollMaster cutting tables achieve millimetre precision with various material types, from delicate silk to technical fabrics up to 25 mm thick (or even 80 mm for soft materials that can be compressed with dual pneumatic pressure bars in RollMaster Super Plus).

RollMaster fits in many different industries, from roller blind and furniture manufacturing to automotive upholstery and aerospace composites. You can use it with natural fabrics, synthetic materials, leather, vinyl, non-woven materials, and specialised products including insulation materials, filter media and protective textiles.

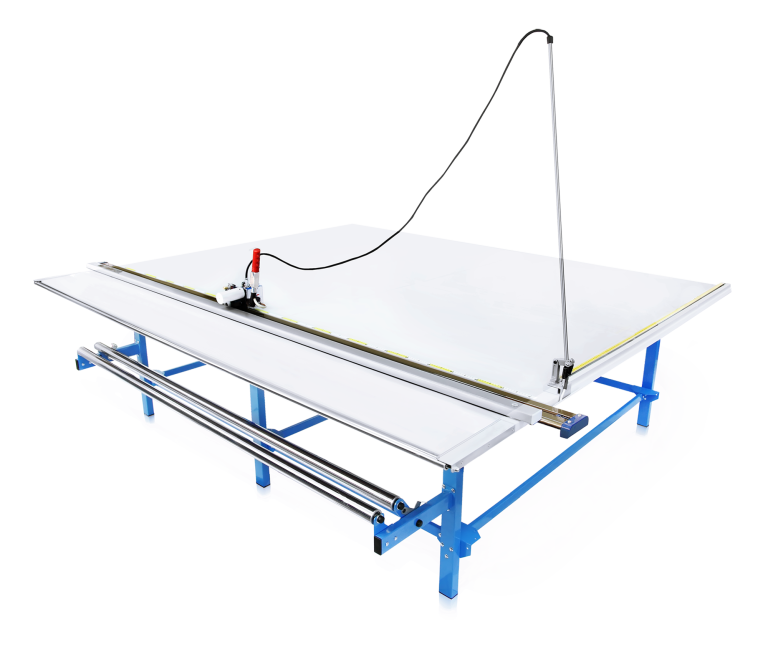

Three different cutting heads work with specific materials – ultrasonic knife for edge welding of synthetics, low- and high-speed rotary cutters for natural fibres.

Specialised Solutions for Roller Blind Production

RollMaster offers specific features for roller blind manufacturers. The table handles both fabric and PVC materials with precision measuring for exact size repeatability. Widths up to 340 cm are supported, including classic roller shades, blackouts, and day-night zebra blinds.

Various accessories for roller blind production are available as extra add-ons.

Cut More in Less Time

Thoughtful design significantly increases efficiency by simplifying repetitive tasks. Dual operation points reduce operator fatigue, touch screen controls with predefined settings in RollMaster PRO minimise setup time. The guide rail speeds up material positioning and LED backlight reduces material waste by helping detect fabric faults.

Works with multiple materials — from roller blinds and upholstery to filtration media, carbon fibres, foam, canvas, vinyl, kevlar, pre-preg composites and many others.

RollMaster series includes multiple models, each designed for different production needs — from manual handling to ultrasonic precision — with flexible configuration options.

Every RollMaster can be

configured to your needs

Choose dimensions and equipment that match your production goals.

Create your custom setup with our online tool.

RollMaster.

Built for various production challenges

RollMaster is a multi-purpose cutting table for precise cutting of materials into custom formats.

We designed the RollMaster series to fill a real gap we saw in the industrial cutting table market — something between basic manual cutting and expensive automated solutions that many companies can’t afford or don’t need.

While Industry 4.0 solutions demand huge infrastructure investments, RollMaster gives you precision cutting for a fraction of the price. We call it smart simplicity because it delivers real results and is affordable for companies of each size.

RollMaster is a versatile cutting table, which is perfect for accurate cutting of material into formats.

A modular cutting table system for precise processing of rolled materials into custom formats.

Every RollMaster can be tailored to your needs

Choose dimensions and features to find your ideal setup in minutes.