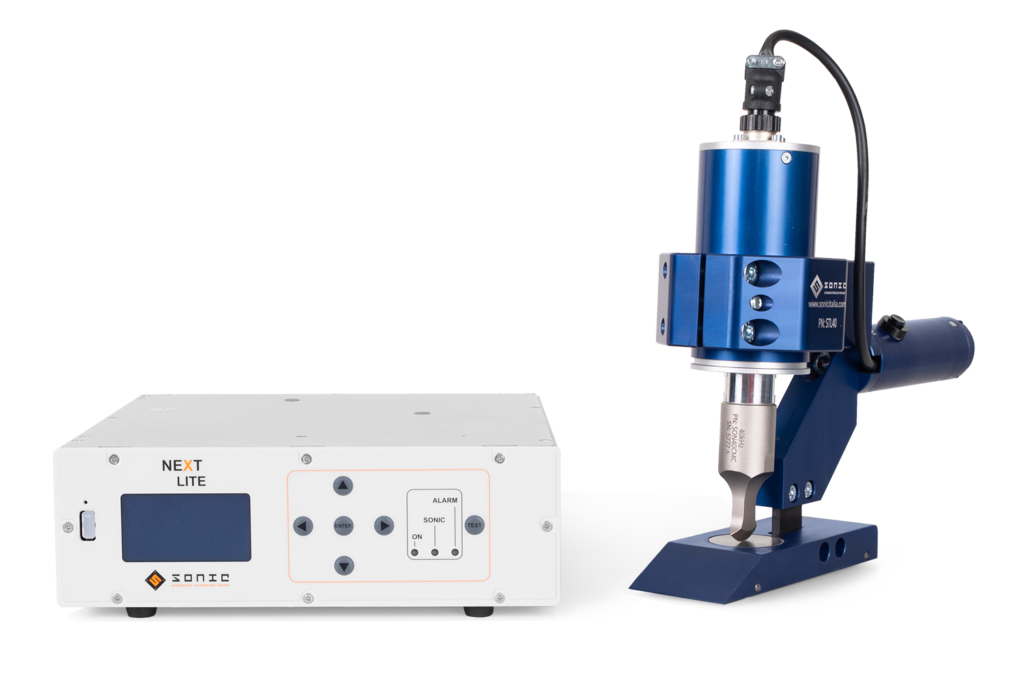

NEXT LITE DESK + STL-40 is an ultrasonic cutting kit for synthetic fabrics.

Thanks to ultrasound technology, the material is not only cut but its edges are automatically sealed, eliminating fraying.

Main Features

- cuts and welds simultaneously

- eliminates the need for seams or stitches

- produces no waste, burning or toxic fumes

- consumes less energy compared to electric knives

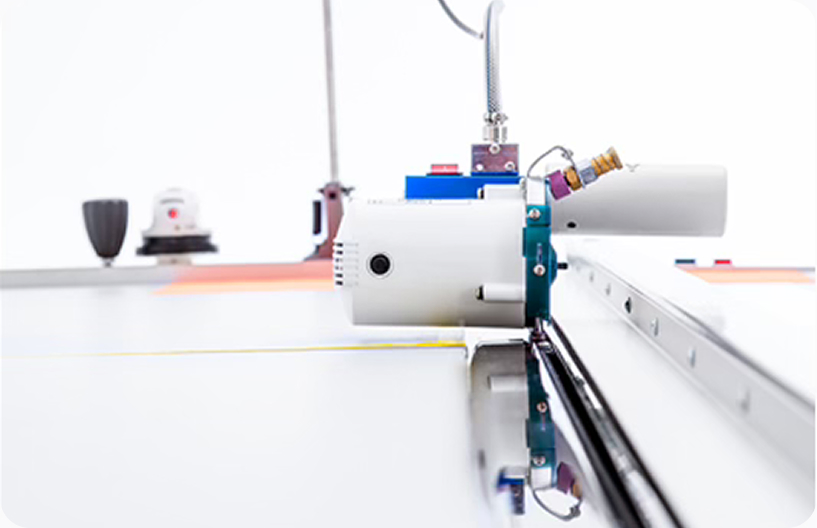

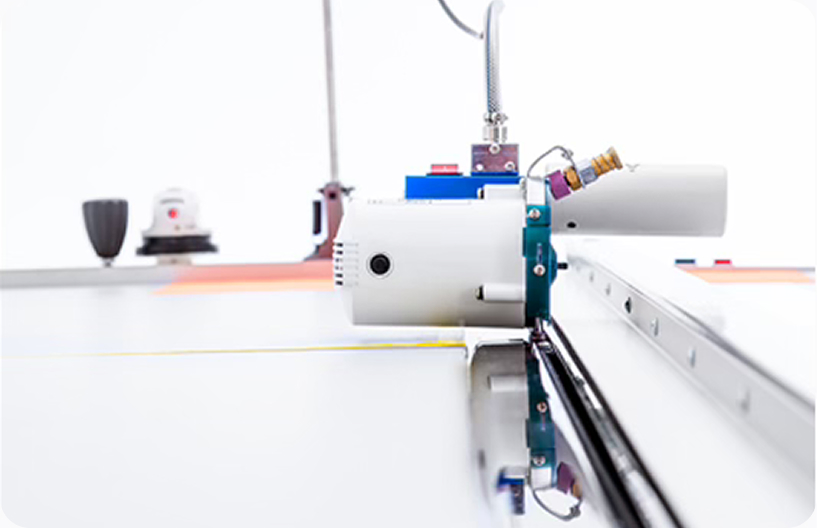

- can be easily installed on cutting tables

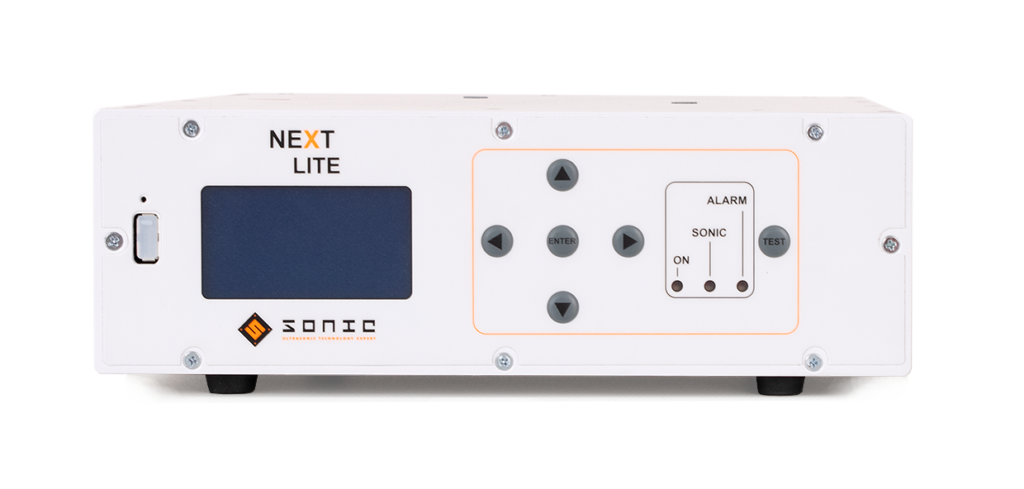

The Generator

NEXT LITE DESK is compact, lightweight, and easy to handle. Multi-frequency technology makes it highly versatile, allowing operation with various sonotrodes for different applications.

It can also function as a PLC and provides real-time control of up to eight parameters.

The front display and directional keys enable fast and intuitive adjustment of all settings.

How does the ultrasonic technology work?

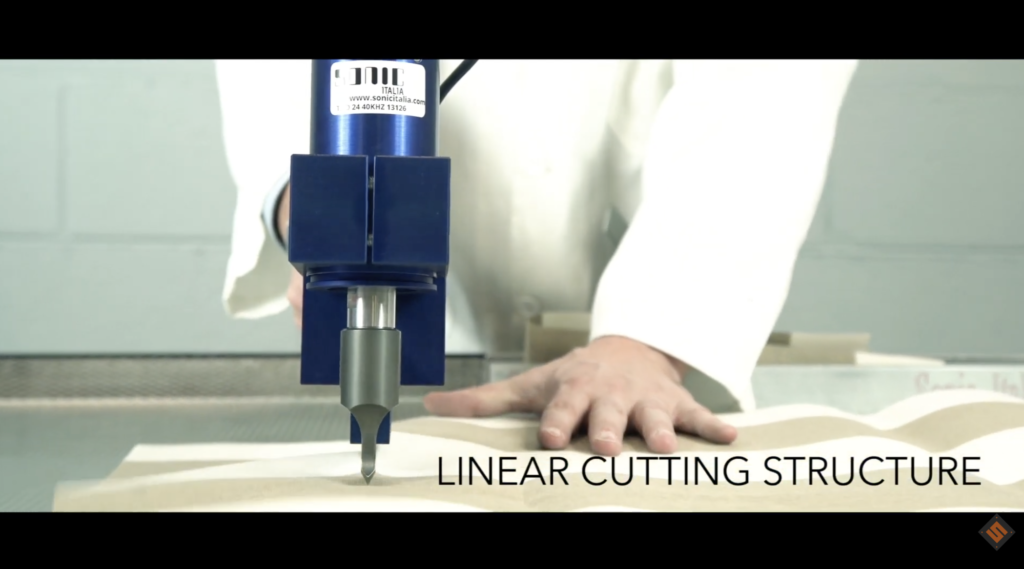

The high-frequency mechanical movement of the vibrating sonotrode combined with the compressive force between the latter and the contrast wheel generate heat, due to the friction that occurs at the point where the sonotrode comes into contact with the material. The heat generated by friction allows the material to be cut and welded at the point of contact between the sonotrode/material, giving the welded component a high degree of elasticity, permeability and absorption.

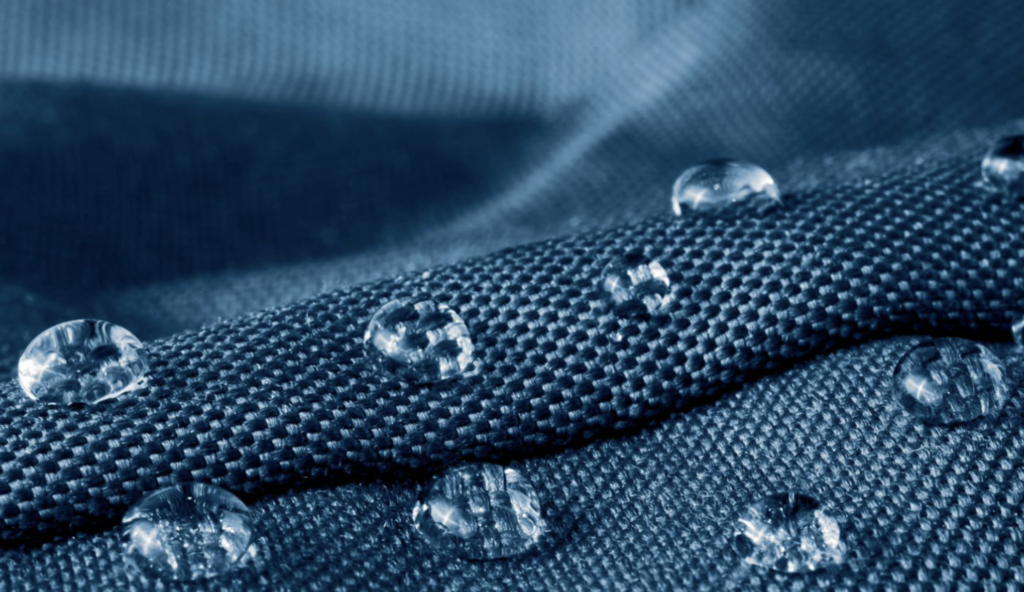

The synthetic fabrics that work best with ultrasonic cutting machinery are those that contain thermoplastics with similar melting temperatures and compatible molecular structures. Polyesteris considered to be the most suitable synthetic material to be subjected to ultrasonic applications.

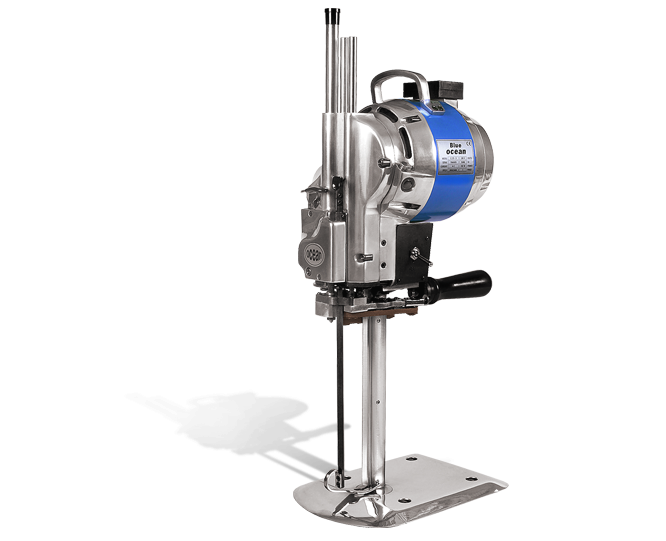

The Cutter

STL40 is ideal for longitudinal manual cutting operations.

Its design is optimized for easy installation on cutting tables, featuring two sliding wheels and a steel plate with a special surface hardening treatment.

The anodised aluminium frame ensures durability and light weight.

Maintenance & Support

Ultrasonic knife has only one replacement part, which is a sonotrode. It doesn’t require sharpening.

We provide full support in three key areas:

service and spare parts

fast response and spare parts shipped within 24 hours

video tutorials

24/7 access to troubleshooting guides

online help

chat with our specialists when necessary

Applications

Ultrasonic technology is commonly applied in the textile/non-woven industry.

The fields of application are synthetic fabrics and acrylic materials, such as honeycomb, synthetic leather, PVC, glass fibre, prepreg carbon fibre, kevlar, polyester, film and blends of synthetic material with cotton.

Frequently Asked Questions

What materials can RollMaster cut? Will it cut mine?

RollMaster can cut a wide range of materials including most woods, plastics, foams, fabrics, and soft metals like aluminum. If you’re unsure whether it can handle your specific material, feel free to contact us with details—chances are, it can!

How much does maintenance and service cost?

Maintenance and service costs can vary depending on usage and specific needs. We offer flexible support options to suit different requirements—please contact us for more details.

How long is the warranty?

We provide a standard 1-year warranty for all B2B customers.

Technical Specification

Table

| Width | any size |

| Length | any size |

| Height | 86–90 cm, adjustable |

| Frame | powder-coated steel profiles |

| Table top | MDF chambers with 6 mm thick HDPE board |

| Power | 2.2 kW |

| Voltage | 230 V |

Interested in this product?

Contact us to discuss your requirements and get a quote.

RollMaster Super cuts rolled materials precisely to the exact formats. Perfect for window blinds, curtains, upholstery and bedding producers who need fast, accurate cuts every time.

Built with a lightweight yet incredibly strong construction that lasts decades, not years.

The thick 25 mm, edge-sealed tabletop resists warping and damage from daily industrial use.

Main Features

- cuts automatically at 1 m/s

- 1 mm cutting precision

- handles rolls up to 320 cm wide

- expandable with LED backlight, speed adjustment and more

RollMaster Super cutting height is 5 mm.

For thicker materials, check out Super Plus model.

Thanks to the modular design, you can create a table tailored to your needs. Start with basic setup, add extensions later as your business grows.

Technical Specification

Cutting Table

| Cutting width | up to 320 cm |

| Length | 200 – 500 cm or other on request |

| Height | 86-89 cm, regulated |

| Frame | powder coated steel profiles |

| Table top | 25 mm, 2 mm PVC framed |

Cutting Device

| Cutting width | up to 320 cm |

| Length | 200 – 500 cm or other on request |

| Height | 86-89 cm, regulated |

| Frame | powder coated steel profiles |

| Table top | 25 mm, 2 mm PVC framed |

Control Features

| Cutting width | up to 320 cm |

| Length | 200 – 500 cm or other on request |

| Height | 86-89 cm, regulated |

| Frame | powder coated steel profiles |

| Table top | 25 mm, 2 mm PVC framed |

Other

| Cutting width | up to 320 cm |

| Length | 200 – 500 cm or other on request |

| Height | 86-89 cm, regulated |

| Frame | powder coated steel profiles |

| Table top | 25 mm, 2 mm PVC framed |

Simple Setup Process

Assemble RollMaster yourself and get started the same day. With our video tutorial, the installation process is as simple as joining lego bricks.

Moreover, the operator learns how to work with it in 30 minutes. No special training needed – just measure, set, and cut. Simple as that.

Watch the video and see how easy it is.

Send samples of your materials for testing

RollMaster Super cuts almost any kind of thin materials including cotton, linen, denim, silk, woven fabric, leather, polyester, films, technical textiles, synthetic fibres, filter materials and much more.

Not sure if your materials will cut perfectly?

Send us samples and receive a free video report with our expert analysis.

Maintenance & Support

Built to last decades, backed by support when you need it. Focus on production, we handle the rest.

assembly of the table

Step-by-step videos make assembly simple

service and spare parts

Fast response and spare parts shipped within 24 hours

video tutorials

24/7 access to troubleshooting guides

expanding the system

Frequently Asked Questions

What materials can RollMaster cut? Will it cut mine?

RollMaster can cut a wide range of materials including most woods, plastics, foams, fabrics, and soft metals like aluminum. If you’re unsure whether it can handle your specific material, feel free to contact us with details—chances are, it can!

How much does maintenance and service cost?

Maintenance and service costs can vary depending on usage and specific needs. We offer flexible support options to suit different requirements—please contact us for more details.

How long is the warranty?

We provide a standard 1-year warranty for all B2B customers.

Every RollMaster can be tailored to your needs

Choose size and features that match your production goals. Find your ideal setup in minutes.