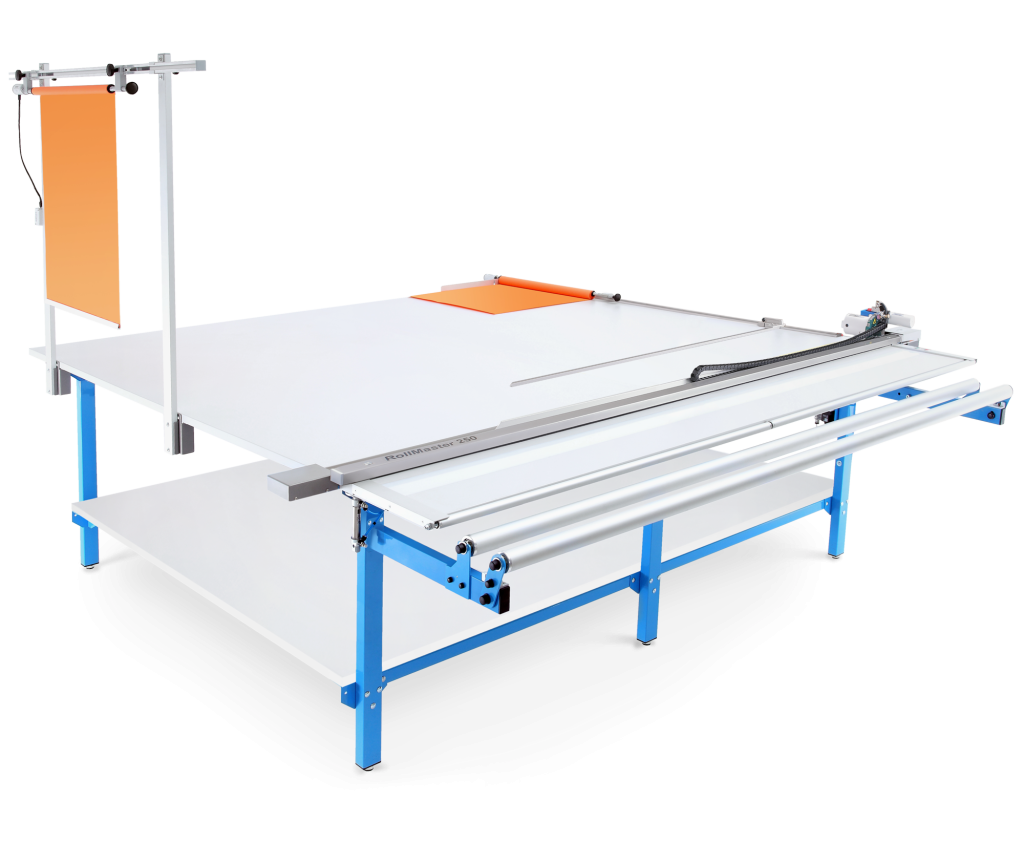

RollMaster Super Configurator

Choose from several table sizes below.

Make sure the table is wide enough — if you cut 300 cm wide fabric, you need at least a 300 cm wide table.

Choose unrolling options to match your production needs and material types. You can select more than one.

Standard fabric feeder

This is our basic solution. Comfortable and fully integrated with the table. Supports rolls up to 35 cm in diameter and weighing up to 40 kg.

The 3-position adjustment system adapts to various roll sizes.

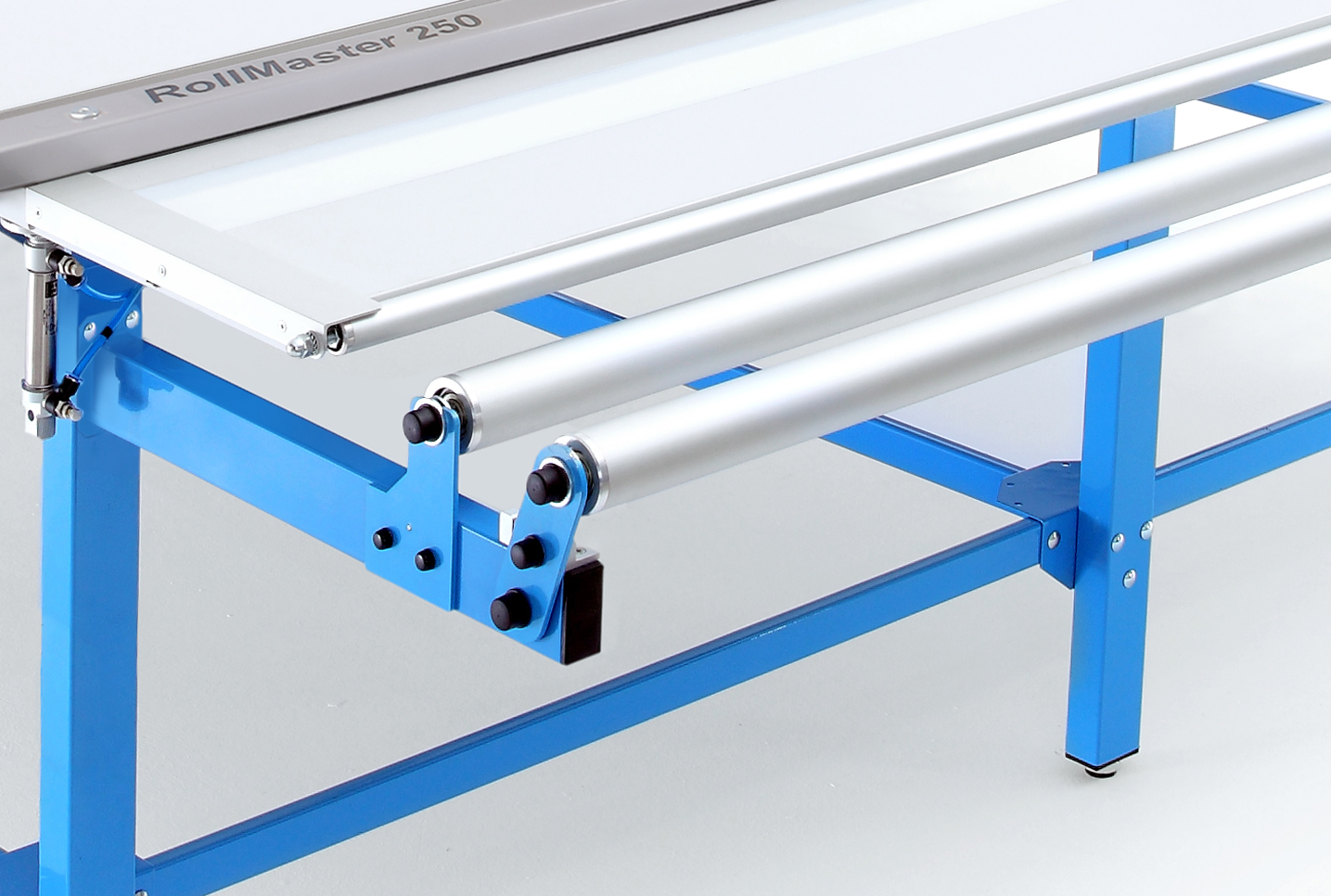

Stationary unwinder

An external unwinder can be used as an alternative to a built-in one. If you have rolls larger than 35 cm in diameter, it’s one of the best options to choose.

EasyRoll S1 handles rolls up to 80 cm in diameter and 60 kg in weight (up to 100 kg as an option).

EasyRoll S2 handles two rolls, with a diameter of 50 cm each and a total capacity of 120 kg.

The set includes metal fixing cones for inner tubes with diameters up to 90 mm.

Mobile unwinder - EasyRoll M9

EasyRoll M9 offers flexible capacity options: it holds up to 9 rolls at 20 cm diameter or 5 rolls at 40 cm diameter, with a maximum weight capacity of 300 kg.

The unwinder enables simultaneous or sequential unwinding from multiple rolls of various dimensions.

It features secure holders that prevent rolls from falling out during operation.

Choose a measuring tool to set the length of your cut sections.

For pieces exceeding the table length, you might use the electronic counter with display.

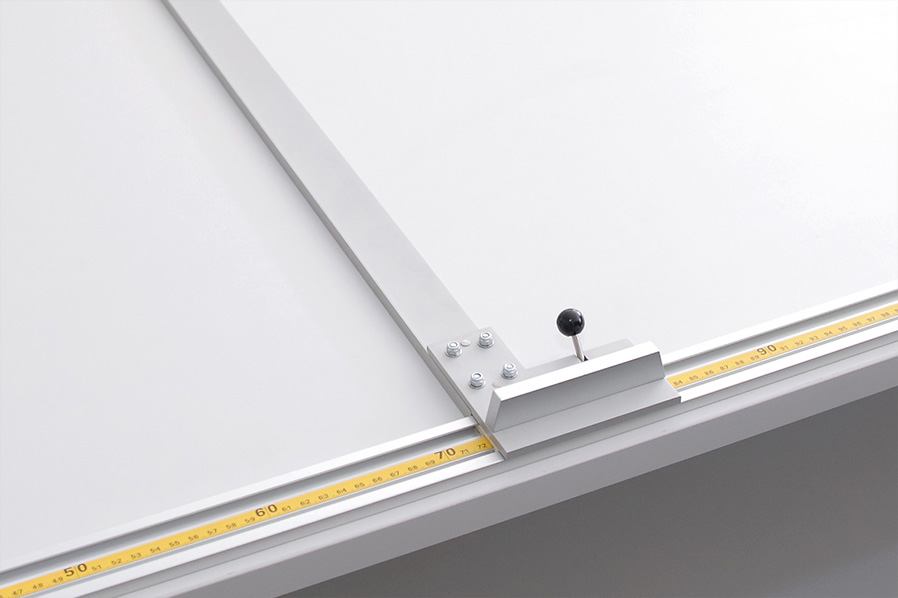

Measuring slider

The slider with a fixed guide strip allows for quick adjustment to the desired cutting length.

The regulated guide strip enables angle adjustments and is longer than the fixed strip version.

The laser guide projects a line onto the table surface. We recommend using the laser primarily for narrower widths — below 250 cm.

Digital meter

The digital meter with an encoder wheel is essential when cutting materials longer than the table.

The encoder wheel tracks the material movement while the digital display shows real-time length readings.

Now you can choose optional table equipment that provides additional functions.

LED backlight

This feature helps detect errors in the fabric without the need for strong overhead lighting.

The backlighting effectively illuminates any defects, making it possible to cut around defective section. This can significantly reduce material waste.

The backlight window is 20 cm wide and runs along the entire table length.

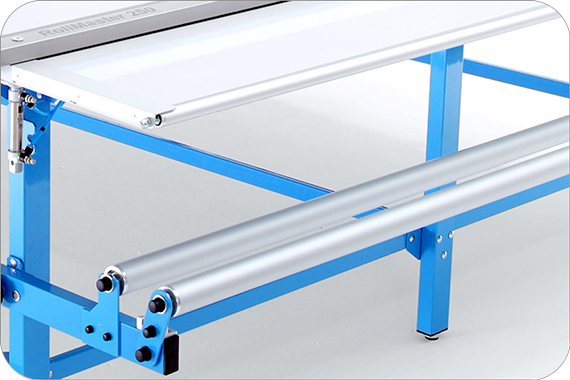

Bottom shelves

Fabric rolls and accessories can be stored on the lower shelves. This is a useful solution if you have limited space.

The table frame is designed to allow lower shelves to be attached later, even if they were not selected at the time of purchase.

Finally, you can choose additional equipment, such as devices useful for the production of roller blinds or a set of spare parts.

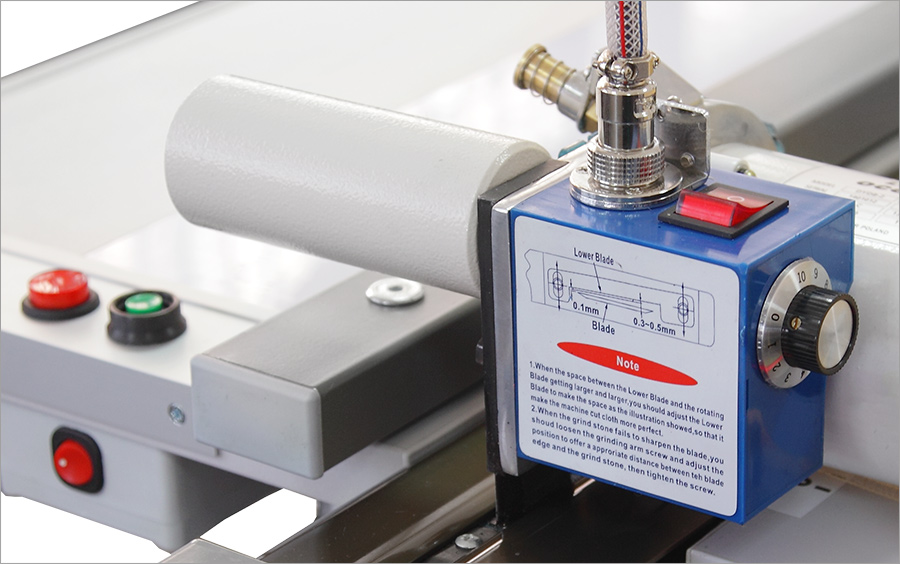

Roller blind winder

The roller blind winder is a very useful tool designed for rolling material onto the tube. It speeds up the preparation of roller blinds and helps to keep the material in a straight line.

It is operated automatically using a foot pedal, which frees up both hands. The winding speed can be adjusted smoothly.

The standard version allows the use of tubes up to 38 mm (1.5 inches) in diameter.

The high version allows tubes up to 50 mm (2 inches) in diameter. Unlike the standard version, it can be mounted on either side of the table.

The stronger version is designed to wind larger blinds onto tubes with diameters up to 60 mm (2.4 inches).

Control frame for roller blinds

The control frame helps verify that the roller blind is rolled up correctly.

The roller blind is rolled up and down using a chain mechanism or an electric motor.

The grippers for the tube are adjustable. The test window measures 2.5 m, with wider versions available on request.

You’ve configured your perfect setup —

now let’s make it happen.

Get your custom quote and start boosting your productivity today!

Ready to Upgrade Your Cutting Room?

Complete the form below to receive a personalized quote based on your configuration.

Your comments