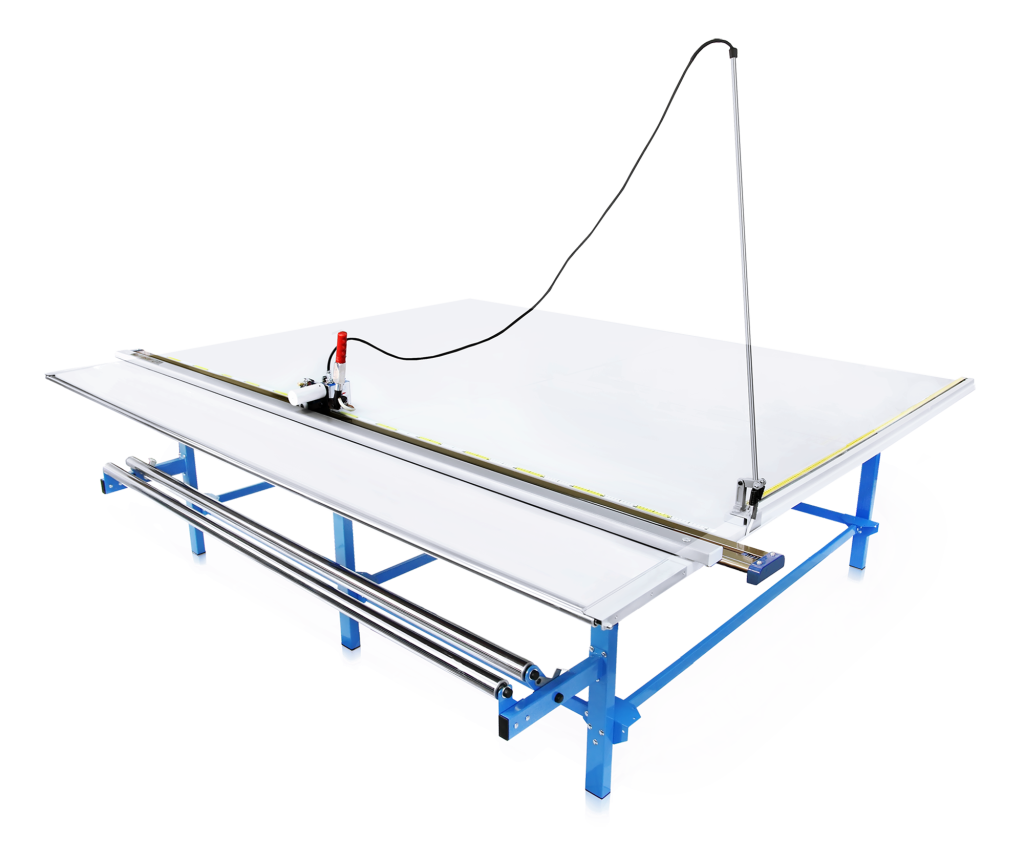

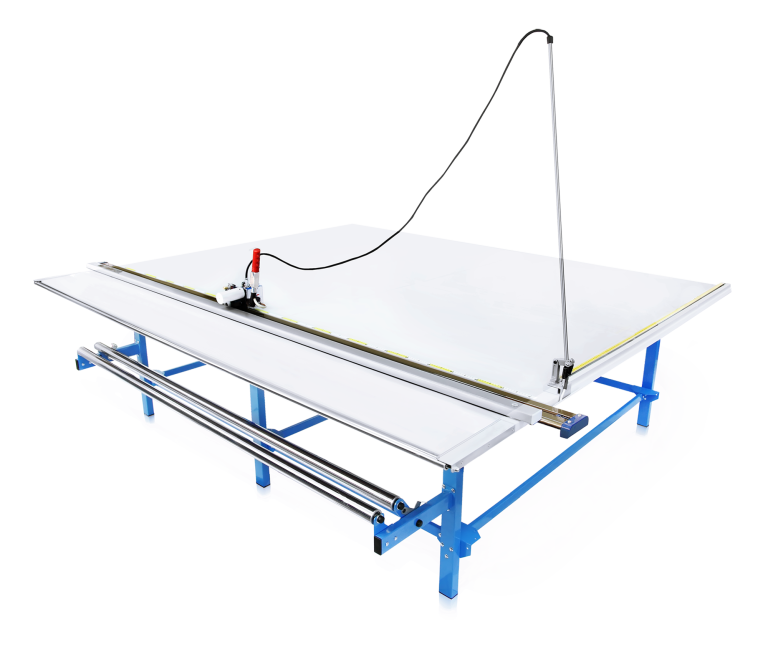

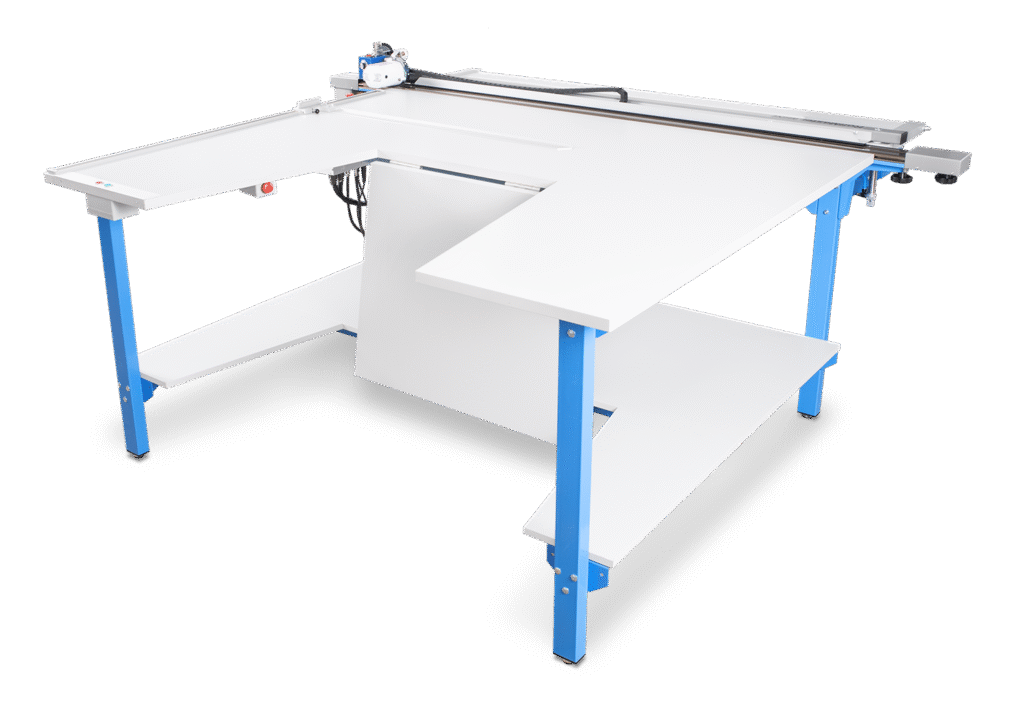

WindMaster combines rewinding, measuring, and cutting in one compact unit. Fabric is manually rewound from a basket on one side onto the tube placed on rollers on the opposite side.

Super version is a semi-professional model featuring automatic cutting and manual winding.

Main Features

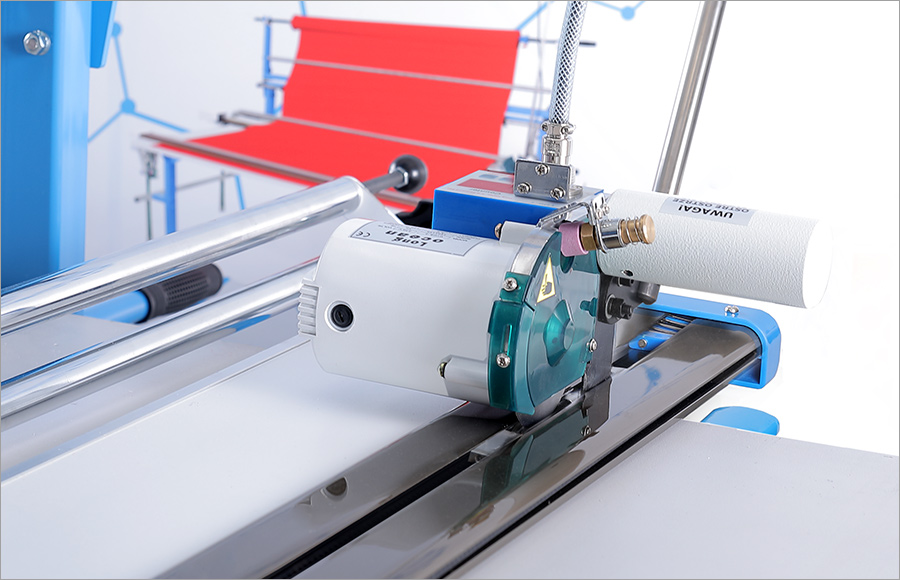

- high-speed automatic cutter

- 1 mm rewinding precision

- pneumatic holding bar

- handles rolls up to 320 cm wide

WindMaster Super features manual rewinding.

If you prefer automatic winding, check out the PRO model.

Construction

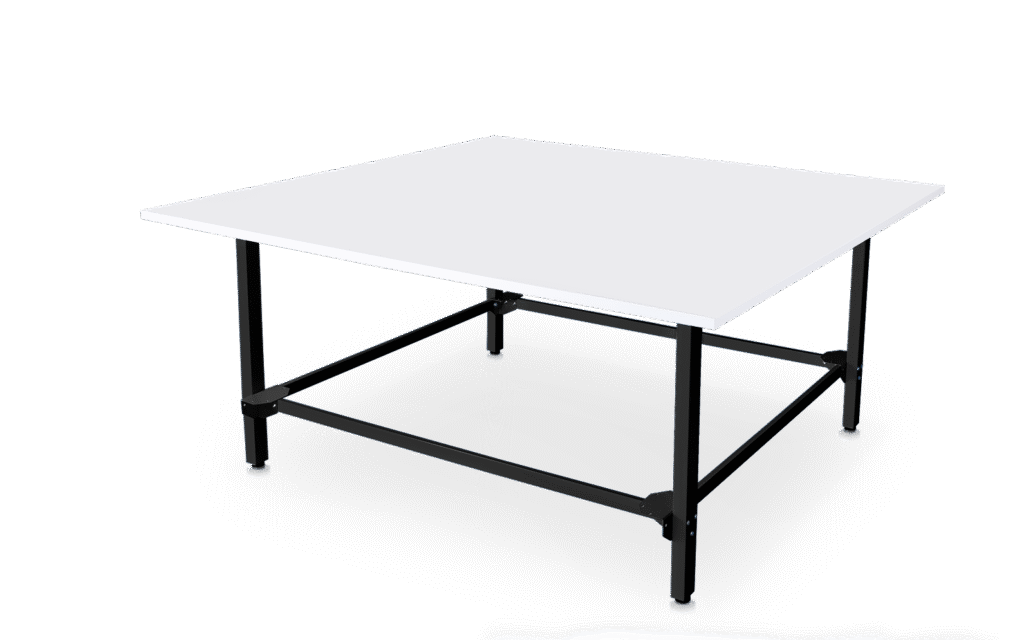

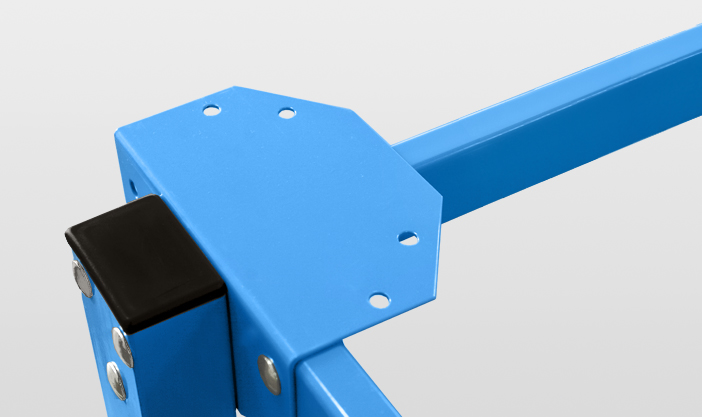

WindMaster is built on a light but very rigid frame, powder-coated. The special girder nodes provide lightweight construction with high stiffness. All aluminum components are anodised, giving them a modern look and preventing staining.

The 25 mm thick table top has a hardened surface and strong 2 mm PVC edging, which protects the table edges.

Measuring

The high-precision digital counter shows the current length during the rewinding process with an accuracy of 1 mm.

Not sure which model is right for you?

Contact us to schedule a free online meeting and we will guide you through our offer.

Or use our Product Advisor to help you select the best equipment.

The modular design lets you create a table tailored to your needs.

Use WindMaster Super configurator to customise it.

Simple Setup & Easy Operation

Assemble the WindMaster yourself and get started the same day. The installation comes down to joining elements in simple steps shown in the assembly manual and video tutorial. No technical skills required.

Operating the table is easy to learn in one day. No special training needed — just unroll, measure, and cut.

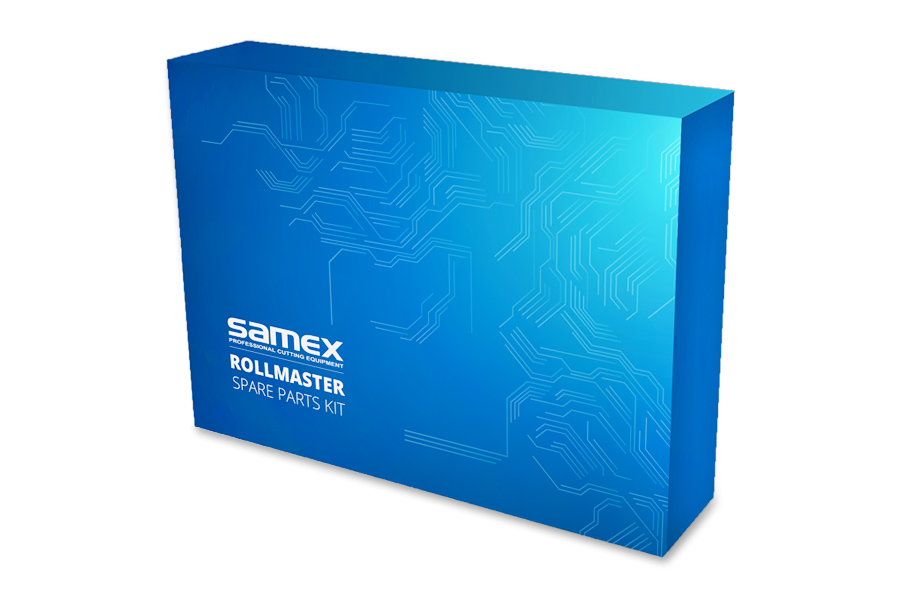

Maintenance & Support

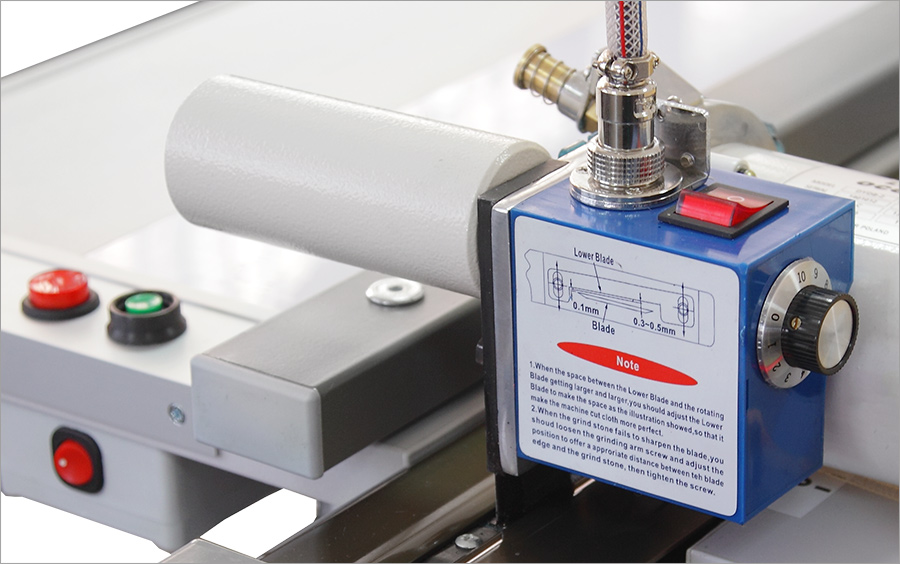

WindMaster Super is designed for long-term use without the need for servicing. The maintenance is just cleaning, replacing blades, sharpeners and carbon brushes. All of them are available in an optional spare parts kit.

Each WindMaster includes complete support package. We offer full post-warranty service and fast access to spare parts available by courier service.

We provide full support in four key areas:

assembly of the table

step-by-step manual for simple assembly

service and spare parts

fast response and spare parts shipped within 24 hours

video tutorials

24/7 access to troubleshooting guides

online help

chat with our specialists when necessary

Applications

WindMaster Super works for fabric wholesalers, curtain manufacturers, material pre-processing operators, and any application requiring precise rewinding.

From canvas to felt, vinyl or paper – it gives 1 mm rewinding precision for every material type.

Frequently Asked Questions

What materials can RollMaster cut? Will it cut mine?

RollMaster can cut a wide range of materials including most woods, plastics, foams, fabrics, and soft metals like aluminum. If you’re unsure whether it can handle your specific material, feel free to contact us with details—chances are, it can!

How much does maintenance and service cost?

Maintenance and service costs can vary depending on usage and specific needs. We offer flexible support options to suit different requirements—please contact us for more details.

How long is the warranty?

We provide a standard 1-year warranty for all B2B customers.

Technical Specification

Cutting Table

| Cutting width | up to 270 cm |

| Length | 200–500 cm or other on request |

| Height | 86–89 cm, regulated |

| Frame | powder coated steel profiles |

| Table top | 25 mm, 2 mm PVC framed |

| Bottom shelves | 18 mm, optional |

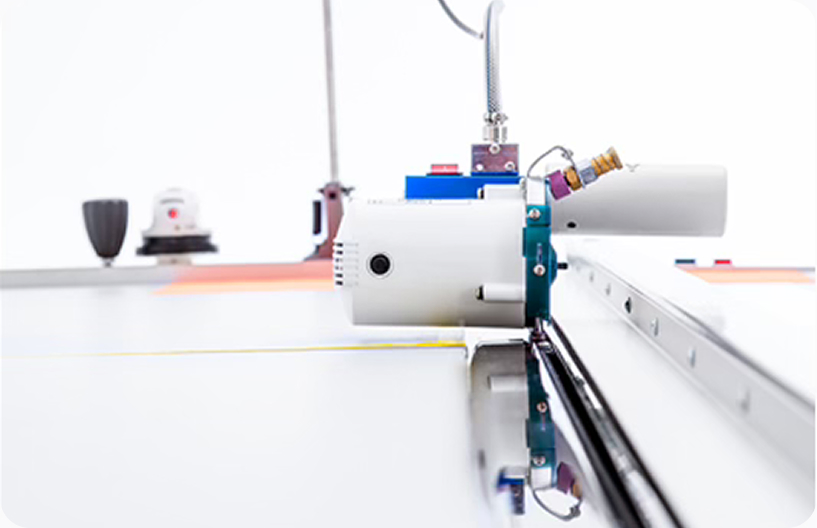

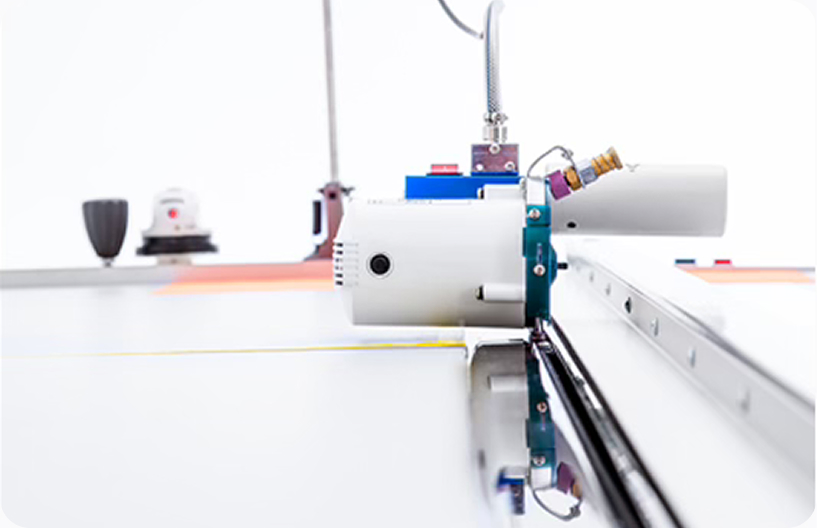

Cutting Device

| Operation | manual |

| Cutting height | 5 mm |

| Cutting precision | 1 mm |

| Protection equipment | blade covers, start lock when the holding bar is raised |

| Blade speed | 12000 rpm |

| Power | 130 W |

| Voltage | 230 V |

Control Features

| Control buttons | manual switch in the cutter hand, table button and foot pedal for holding bar operation |

| Layer counter | yes, with editing function |

| Blade speed adjustment | optional |

Other

| Holding bar | pneumatic, single |

| Fabric feeder | built-in or external |

WindMaster Super can be

tailored to your needs

Choose size and options that match your production goals.

Find your ideal setup in minutes.

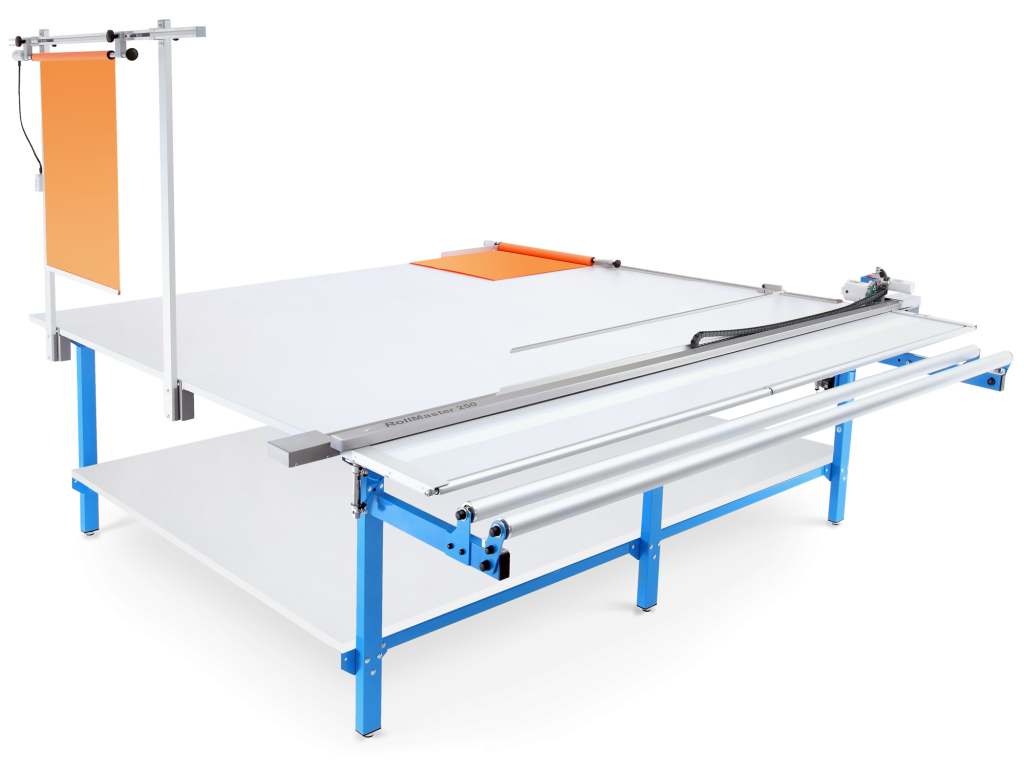

RollMaster Super cuts rolled materials precisely to the exact formats. Perfect for window blinds, curtains, upholstery and bedding producers who need fast, accurate cuts every time.

Built with a lightweight yet incredibly strong construction that lasts decades, not years.

The thick 25 mm, edge-sealed tabletop resists warping and damage from daily industrial use.

Main Features

- cuts automatically at 1 m/s

- 1 mm cutting precision

- handles rolls up to 320 cm wide

- expandable with LED backlight, speed adjustment and more

RollMaster Super cutting height is 5 mm.

For thicker materials, check out Super Plus model.

Thanks to the modular design, you can create a table tailored to your needs. Start with basic setup, add extensions later as your business grows.

Technical Specification

Cutting Table

| Cutting width | up to 320 cm |

| Length | 200 – 500 cm or other on request |

| Height | 86-89 cm, regulated |

| Frame | powder coated steel profiles |

| Table top | 25 mm, 2 mm PVC framed |

Cutting Device

| Cutting width | up to 320 cm |

| Length | 200 – 500 cm or other on request |

| Height | 86-89 cm, regulated |

| Frame | powder coated steel profiles |

| Table top | 25 mm, 2 mm PVC framed |

Control Features

| Cutting width | up to 320 cm |

| Length | 200 – 500 cm or other on request |

| Height | 86-89 cm, regulated |

| Frame | powder coated steel profiles |

| Table top | 25 mm, 2 mm PVC framed |

Other

| Cutting width | up to 320 cm |

| Length | 200 – 500 cm or other on request |

| Height | 86-89 cm, regulated |

| Frame | powder coated steel profiles |

| Table top | 25 mm, 2 mm PVC framed |

Simple Setup Process

Assemble RollMaster yourself and get started the same day. With our video tutorial, the installation process is as simple as joining lego bricks.

Moreover, the operator learns how to work with it in 30 minutes. No special training needed – just measure, set, and cut. Simple as that.

Watch the video and see how easy it is.

Send samples of your materials for testing

RollMaster Super cuts almost any kind of thin materials including cotton, linen, denim, silk, woven fabric, leather, polyester, films, technical textiles, synthetic fibres, filter materials and much more.

Not sure if your materials will cut perfectly?

Send us samples and receive a free video report with our expert analysis.

Maintenance & Support

Built to last decades, backed by support when you need it. Focus on production, we handle the rest.

assembly of the table

Step-by-step videos make assembly simple

service and spare parts

Fast response and spare parts shipped within 24 hours

video tutorials

24/7 access to troubleshooting guides

expanding the system

Frequently Asked Questions

What materials can RollMaster cut? Will it cut mine?

RollMaster can cut a wide range of materials including most woods, plastics, foams, fabrics, and soft metals like aluminum. If you’re unsure whether it can handle your specific material, feel free to contact us with details—chances are, it can!

How much does maintenance and service cost?

Maintenance and service costs can vary depending on usage and specific needs. We offer flexible support options to suit different requirements—please contact us for more details.

How long is the warranty?

We provide a standard 1-year warranty for all B2B customers.

Every RollMaster can be tailored to your needs

Choose size and features that match your production goals. Find your ideal setup in minutes.